8 Types of Utility Blades [GUIDE]

There are 8 common types of utility blades depending on their shape and application:

- Trapezoid Blades

- Hook Blades

- Concave Blades

- Snap-Off Blades: 9 and 18mm + without segments

- Long Utility Blades

- Serrated / Toothed Utility Blades

- Safety Blades

- Scalpels, Precision Blades or Craft Blade

Each particular type of utility blade has its own features, applications, methods of use and design. Below we will try to describe each type of utility blade in as much detail as possible.

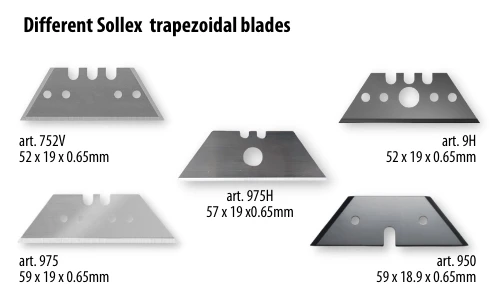

Trapezoid Blades for Utility Knives

The most common blade on the market for utility knives is the so-called utility trapezoid blade. The terms "trapezoidal" or "all-round" blade are well suited.

The most common blade on the market for utility knives is the so-called utility trapezoid blade. The terms "trapezoidal" or "all-round" blade are well suited.

Description: Utility trapezoidal blades are trapezoid-shaped, have a single cutting edge, and can cut a wide range of materials. Certain blades are better suited for cutting some tougher materials because of a coating on the blade cutting edge. For situations when a shorter, more robust knife blade tip is required, a short straight blade (52mm instead of 60mm) is advised since it is more stable and locks in better. The upper side of the utility trapezoid blade features 2 or 3 mounting slots for improved handle attachment.

Use as reference Sollex blades: 975, 975P, 975PT or 9P, 9PT, 9S

Users of trapezoid utility blades: floor and roof installers, builders and construction workers, warehouse and logistics staff, craftsmen, industrial machines and many others.

Standard dimensions: 52x19.0.65mm and 59/60x19x0.65mm.

Materials to cut / application: 59mm long blades are great to cut drywall (gypsum board), insulation foam boards, polystyrene (EPS, XPS), polyurethane, foam insulation boards, roofing materials such as asphalt shingles, roofing felt, and rubber membranes, carpet and underlayment, paper and cardboard, films and many more.

Main uses for shorter 52mm long trapezoidal blades are carpeting and flooring, safety knives, and industrial machines.

Manufacturers of trapezoidal utility blades: Sollex, Lutz, Mozart, Stanley, Milwaukee, Hilti, Fiskars, OLFA, Martor, Irwin, Gerber etc

Manufacturers of trapezoidal utility blades: Sollex, Lutz, Mozart, Stanley, Milwaukee, Hilti, Fiskars, OLFA, Martor, Irwin, Gerber etc

Mountable in all standard utility knives, t ex: The ordinary long trapezoid blades are 59 / 60mm long and fit most utility knives on the market. Check the fit of trapezoidal blades and knives based on the example of the Sollex 975P blade.

Sollex Utility Blades

Sollex offers both shorter and longer trapezoidal-shaped blades for professional use. The blade series is labeled PRO. The blades are 59/60mm long and fit most knives on the market. Some blades are coated on the edge, making them more suitable for cutting some harder materials. You can read more about Sollex's qualities and coatings here. Sollex utility blades are adapted for our knives Utility knife Mozart S2 1002.00, Construction knife 2000 and Dolphin knife 1280, but fit most knives on the market.

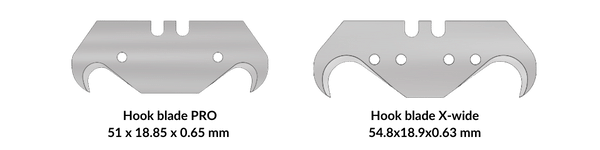

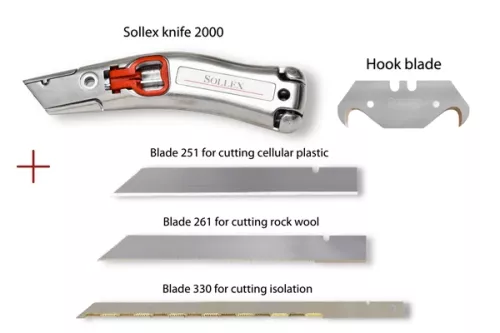

Hook Blade for Utility Knives

A hook blade is a blade with a hook at either end used to cut through thick materials without damaging the material underneath. Hook blades are used in construction, roofing, flooring, and other work requiring cutting difficult materials.

A hook blade is a blade with a hook at either end used to cut through thick materials without damaging the material underneath. Hook blades are used in construction, roofing, flooring, and other work requiring cutting difficult materials.

Description: Hook blades are unique in that they have a hooked shape that allows them to easily cut materials without catching or jamming. The hook shape also makes it a safer option for cutting materials in confined spaces by preventing the blade from accidentally cutting into underlying materials or surfaces.

Use as reference Sollex blades: 10, 10P, 10PT

Users of hook blades: Hook blades are used by professionals such as contractors, flooring installers and roofers, as well as do-it-yourselfers who need a reliable cutting tool for a variety of home improvement projects.

Standard dimensions: Hook blades for utility knives are most commonly found in the standard 51x19x0.63mm size, but there are some smaller sizes available, such as the 48x19x0.65mm hook blade for Stanley utility knives.

Materials to cut / application: hook blades are designed to cut carpet, linoleum, roofing shingles, and other materials difficult to cut with standard straight blades.

Manufacturers of utility hook blades: Sollex, Mozart, Lutz, Milwaukee, Martor, Wolfcraft, DeWalt

Manufacturers of utility hook blades: Sollex, Mozart, Lutz, Milwaukee, Martor, Wolfcraft, DeWalt

Mountable in all standard utility knives, t ex: Typically used in utility, construction or dolphin knives.

Hook blades are a versatile cutting tool that can be used for a variety of applications, such as:

- to cut through tough or abrasive materials. Hook blades are especially useful for cutting through materials that are difficult to slice with a standard blade, such as carpet, vinyl, roofing felt, rubber, and various types of fabrics.

- for roofing materials. As mentioned earlier, hook blades are commonly used in roofing work to cut through roofing shingles, tar paper, and other roofing materials.

- for flooring materials. Hook blades are also frequently used in flooring work to cut through linoleum, vinyl, and other types of flooring materials.

- repair and construction work. Hook blades can be used to cut through various materials in automotive repair, such as trimming upholstery or cutting through rubber or plastic tubing.

- DIY and crafts. Hook blades can be used in various arts and crafts projects, such as cutting through foam board or heavy-duty paper.

High-quality hook blades which fit all STANLEY utility knives

Hook blades are optimal for knives for floor and roof layers. Thus, the hook blade is the one used for utility knives designed for flooring and ceiling construction work. The standard size of a hook blade is 51mm long. An "extra wide" hook blade is 55mm long to be able to cut extra thick carpets. Some Stanley knives can use 51mm long hook blades and some cannot. To force users to use Stanley's 48mm long hook blades, some Stanley knives have been made slightly too shallow so that the 51mm long hook blades just won't fit. Note that it is only the hook blades that do not fit Stanley's carpet knife with hooks. The long straight knife blades fit just fine, as they have exactly the same dimensions as the Stanley knife blades.

Fortunately, Sollex has a great solution for the Stanley knife with a hook blade in the 10STANLEY hook blade which has exactly Stanley's dimensions but the same high quality as Sollex 10P German produced PRO hook blades. You can easily order the 10STANLEY and get a really good hook blade that fits all Stanley knives.

Concave Blades for Utility Knives

Concave blades are hooked utility blades with one cutting edge that are used in pairs with a utility knife to cut and score mostly flooring materials.

Concave blades are hooked utility blades with one cutting edge that are used in pairs with a utility knife to cut and score mostly flooring materials.

Description: Concave blades have a distinctive curved, semicircular or hook-shaped profile. This design makes it easy for the blade to hook and cut through flexible or tough materials like carpet and flooring, or to cut around pipes and tricky corners.

Use as reference Sollex blades: 16, 16P, 16PT

Users: mostly floor and roof layers, construction workers

Standard dimensions: 59x19x0.65mm

Materials to cut: carpet, linoleum, various underlayments, as well as acrylic panels, LVP, vinyl, rubber and other soft or flexible materials

Manufacturers of concave blades: Sollex, Mozart, Lutz, Stanley

Mountable in all standard utility knives, t ex: Sollex 2000, 1280, 1280B, 1280S utility knives; STANLEY® Classic 99® 10-099, STHT10175-8, STANLEY® FatMax® 10-818, 10-819, 10-789, 10-780, 10-777, 10-778, STHT10424-0, FMHTO-10320, XTHTO-10502 etc. EXCEPT! STANLEY® Titan 10-550, 10-199 199E Fixed Blade Knife

Concave blades can be used to cut roofing materials, particularly soft roofing materials like roofing felt. The hook form of the blade allows for a precise, controlled cut. Concave blades are ideal for cutting soft packing materials including cardboard, thick plastic, and strapping tape. Some amateurs and craftsmen may use concave blades to cut cloth, leather, or other soft materials for their projects.

Because of the concave blade form, the material may also be cut with a pulling action. Once you penetrate the material at the first cutting point and drag the utility knife towards it, the material will cut effortlessly.

There are also extra titanium-coated concave blades that are extra sharp and heavy-duty. They are excellent for cutting abrasive materials such as roofing felt. In this case, try the Sollex PRO Titanium Concave Blade 16PT.

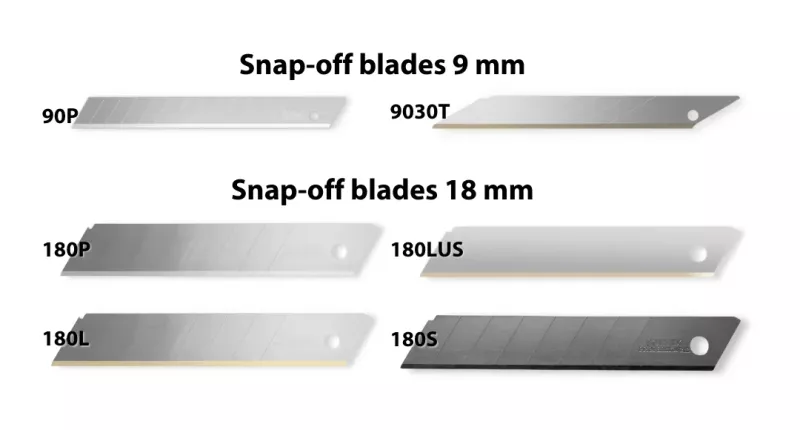

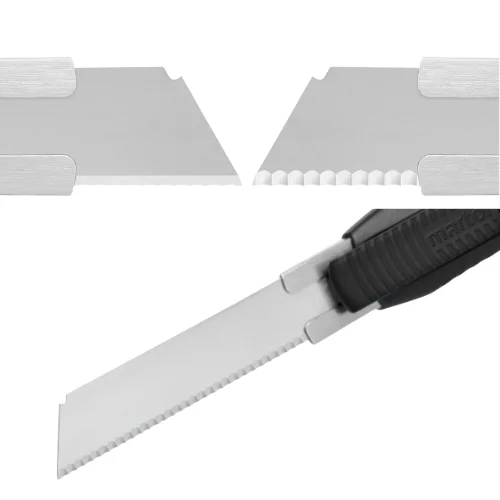

Snap-Off Blade for Utility Snap-off Knives

Utility snap-off blades are blades typically 90-100mm long and 9 or 18mm wide for use in a special utility snap-off knife with a retract function.

The snap-off blade is designed to use only 10mm of the blade at a time. Therefore, use only one blade segment at a time. Leave only about 10 mm of the blade in front. This will prevent damage and provide a better cut. If you want a longer blade, use only unsegmented blades such as the Sollex 180LUS for safety reasons.

9mm Snap Off Blades

Description: 9 mm wide snap-off blades usually have 13 break-off segments.

Use as reference Sollex blades: 90, 90P, 90US

Users: The small snap-off knife is used for various crafts and hobbies, but also for packing and unpacking.

Standard dimensions: 80x9x0.4mm

Materials to cut: For easy cutting jobs, such as cutting thin materials like paper, cardboard, wallpaper, leather, vinyl, film, and wood, small cutter knives with a 9 mm blade are ideal.

Manufacturers of snap-off blades: Sollex, Mozart, Olfa, Lutz, Stanley, NT Cutter, Milwaukee, DeWalt

Mountable in 9 mm snap-of knives, t ex: Olfa SVR-2 9mm snap-off blade knife small (5090), Snap-off blade knife 9mm PRO NT Cutter A-300GR (5190), Utility knife 9mm single (2090), Snap-off knife 9mm NT Cutter S-202P (S202), Milwaukee 48221960 9mm, 48-22-1960 Utility Knife With Metal Lock 9mm, STANLEY® 9mm Snap-Off knives like 0-10-095, STHT 10264-8 9mm TPR Auto Lock Snap-off Knife, 10-150 9mm QuickPoint Snap-off knife, 10409 Dynagrip Snap-off knife 9mm and many more

18mm Snap Off Blades

Description: 18mm wide snap-off blades usually have 8 break-off segments.

Use as reference Sollex blades: 180P, 180, 180LUS

Users: all-round knives for different types of cutting

Standard dimensions: 100x18x0.5mm

Materials to cut: 18mm snap-off knives are used daily for cutting wallpaper, corrugated board, flooring materials, drywall, plasterboard, and polyurethane.

Manufacturers of snap-off blades: Sollex, Mozart, Olfa, Lutz, Stanley, NT Cutter, Milwaukee, DeWalt

Mountable in 18 mm snap-of knives, t ex: 18mm cutter blade fits in all standard 18mm utility snap-off knives like NT-Cutter snap off knife. e.g. NT-Cutter knives 5180 L-500GRP, 7180 L-2000RP, 9180 L-550GP; OLFA 18mm NOL-1, NA-1, OL, PL1, XH1, L1; Milwaukee® 48-22-1961, 48-22-1964, 4932480107, 48229118; STANLEY® STHT 10276, 10265 ABS, 10266 TPR , 10268, 10-280, 10-151, STHT10151-8 Quick Point snap-off knives, STHT10418-8 Dynagrip, Interlock™ Knife 0-10-018 and most other 18mm snap-off knives

Keep in mind that you should replace the blade periodically. Browse our wide range and buy the best blade for your knife.

Snap Off Blades without Breakable Segments

Sollex has utility snap-off blades without segments. These are great because no segments can come off the blade and are perfect for cutting down cardboard and thick materials.

Do you like the idea of using more than 10 mm at a time of your utility knife? Then use blades without segments. These cannot be broken off and are well suited to use up to 70 mm out from the knife. Blades without segments are supplied as standard in the Martor 380001 safety knife. You can order knife blades without segments from Sollex and these are called 180LUS.

Long blades for Utility Knives

The utility knife is advantageously equipped with larger blades that are needed for cutting thicker materials, such as mineral wool or another insulating material. There is no standard for these blades, which are referred to as long blades. The blade's length and cutting edge vary. The most crucial thing to remember is that not all long blades can be integrated into your utility knife; instead, focus on the blade's end and its notches.

It is very common to find long blades serrated or toothed, as it is in this form that they best cut mineral wool and insulation. Below we will list possible variations of long blades that can be fitted into utility knives.

Long blades for cutting thicker insulation materials

The Sollex blade art. no. 330 is 330 mm long (330 x 18.9 x 1.1 mm) with heavy-duty titanium-coated teeth, suitable for cutting thicker insulation. The 1.1 mm thick blade is made of high-quality steel and provides good durability and excellent cutting properties for the professional user. You need a special knife holster (331) which is extra long.

Long blades for cutting rock wool

The 180 mm long blade art. no. 261 is suitable for cutting mineral wool insulation materials and mineral wool boards. The 0.65 mm thick double-sided blade made of quality steel provides good durability for the professional user. 261 stone wool knife blade fits Sollex construction knife (2000). Special holster (300) recommended for safe storage when not in use.

Long blades for cutting fiberglass

Knife blade art. 195 (195 x 15.8 x 0.89 mm), which is adapted for use in industrial production and is particularly suitable for cutting glass wool and rubber. The grinding is 33 degrees for optimal fiberglass cutting.

Long blades for cutting foam

The knife blade art.nr 251 is 160 mm long (160 x 18.9 x 0.65 mm) and is adapted to cut in e.g. cellular plastic, styrofoam, and polystyrene, but also other types of insulation. It is made of 0.65 mm thick quality steel, double ground, which provides good durability for the professional user. Extra holster 300 fits perfectly with this knife blade.

Utility Safety Blades

Safety blades are designed specifically for use with safety knives only. The shape, material, and thickness of the safety blades vary and depend on the model of safety knife in which they are installed. Their main features include the following:

Safety blades are designed specifically for use with safety knives only. The shape, material, and thickness of the safety blades vary and depend on the model of safety knife in which they are installed. Their main features include the following:

- Safety knives often feature rounded cutting blade corners since their primary function is to lessen the possibility of an unintentional cut of the user.

- Materials from which the safety blade can be made: carbon steel, stainless steel, bimetal, and ceramic.

- The shape of safety blades is most often trapezoidal, rectangular, or scalpel-shaped. There is also a special form of safety blades, where the blade itself is concealed and built into a plastic head and they are called concealed safety blades.

- An extra utility blade or a new safety blade from a different brand can't be put into a safety knife that isn't the same make and model. It goes both ways. Manufacturers of safety knives take care so that specially designed knives paired with this particular blade guarantee safety when cutting.

Materials to cut with safety knives and blades: cardboard, tape, plastic film, wrapping, stretch, plastic strapping band, layers of paper, film, foam, polystyrene. Safety knives and cutters are used for opening packages and boxes, cutting strapping material and tapes, tearing shrink wrap, cutting and disposing of packages and much more.

Users of safety knives and blades: safety knives are common among workers in delivery and logistics departments, warehouses, and stores.

Manufacturers of safety knives and blades: Martor, Klever, Slice and others

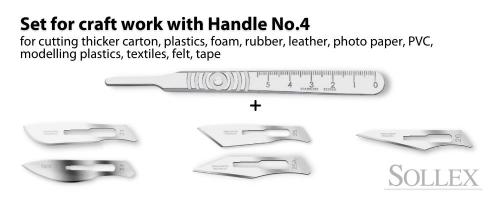

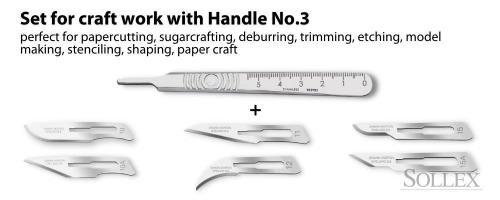

Scalpels, Precision Blades or Craft Blades

There are scalpels for medical and surgical use, scalpels for craft work, and scalpels for industrial use.

Generally, we do not recommend using medical scalpels for industrial use. Scalpel blades can be used to cut graded plastic parts, for example, but it may not be the most appropriate or effective tool for the job. Medical scalpel blades are usually designed for precision cutting of delicate materials such as fabrics or thin films, and may not be strong and durable enough to cut thicker plastic materials.

Typical applications of scalpels: for cutting various materials such as cardboard, paper, wallpaper, plastics, textiles, leather, graphic design, precision cutting or any art and design work where detail, neat cuts and clean edges are required

Users: scalpel is the perfect tool for designers, artists and model makers

Manufacturers of scalpels: Swann Morton, Mozart, Exacto and others

Select the scalpel best for your needs and preferences. Combining various scalpels will help you to quickly design the ideal mix for the current work. The scalpel's handle as well as the blade itself are bought here.

There are many types and shapes of surgical knives designed for different purposes. For example, Swann Morton scalpel blades numbered 10 and 11 have a pointed end and are ideal for very detailed work. At the same time, surgical knives are very sharp, so you need to be cautious and follow safety guidelines when handling them.

TIP: Make sure the scalpel blade and handle are the same size - this is especially important.

Read more on this topic on our blog

Buy Utility Blades Online

Sollex has been delivering utility blades quickly and safely since 1927. You can read more about our product qualities and coatings at product qualities. Can't find what you're looking for? Get in touch with us at +46 35-157500 or info@sollex.se, and we'll help you!

FAQ

Q: What is the most common type of utility blade?

A: The trapezoid blade is the most widely used utility blade. It fits most standard knives and is ideal for cutting drywall, insulation, roofing materials, and packaging.

Q: When should I use a hook blade instead of a straight blade?

A: Hook blades are best for cutting carpet, vinyl, and roofing materials. Their curved design prevents damage to underlying surfaces and makes them safer in confined spaces.

Q: What is the difference between 9mm and 18mm snap-off blades?

A: 9mm blades are slim and precise for crafts and light-duty cutting, while 18mm blades are wider, stronger, and suitable for drywall, flooring, and heavy materials.

Q: What are long utility blades used for?

A: Long blades (160–330 mm) are used for cutting insulation, mineral wool, fiberglass, and foam. Many are serrated to slice through thick or fibrous materials efficiently.

Q: Can I use medical scalpels as utility blades?

A: Medical scalpels cut precisely but are not ideal for heavy-duty or industrial use. For craft and precision work, Sollex offers industrial scalpels and Mozart precision knives designed for non-surgical cutting.

Q: What safety measure should be taken when using standard snap-off blades?

A: For safety and to prevent damage, you should use only one blade segment at a time, leaving only about 10 mm of the blade exposed in front of the knife handle.

Q: What materials are the standard 59mm trapezoid blades recommended for?

A: The 59mm trapezoid blades are ideal for general construction and building materials, including drywall (gypsum board), foam boards (EPS, XPS), roofing materials (shingles, felt), carpets, paper, and general packaging materials.

Q: What is the primary function and safety benefit of the Hook Blade design?

A: Hook blades are designed for a pulling motion to cut through thick materials like carpet, linoleum, and roofing felt without damaging the material or surface underneath. Their hooked shape makes them safer in confined spaces.

Q: When are Concave Blades the ideal cutting tool?

A: Concave blades have a curved profile that makes them ideal for floor and roof layers, specifically for cutting flexible or tough materials like carpet, linoleum, vinyl, and rubber, or for cutting around tricky corners and pipes.

Q: What option is available for users who prefer snap-off knives but need a longer, safer blade extension?

A: Users should use unsegmented snap-off blades (like the Sollex 180LUS). These blades cannot break off, making them suitable for extending up to 70 mm out from the knife for cutting thick materials like cardboard safely.

Q: Why are long utility blades (160mm–330mm) often serrated or toothed?

A: Long blades are typically serrated or toothed because this form allows them to most effectively cut thick, fibrous materials like mineral wool, rock wool, and various types of insulation.

Q: What makes trapezoid blades like the Sollex 975P suitable for most utility knives?

A: The standard trapezoid blades (59/60x19x0.65mm) are universally compatible due to their dimensions and feature standard mounting slots, fitting most utility knife models from various manufacturers on the market.

![8 typer av knivblad för universalknivar [GUIDE] - Sollex blogg](https://cdn.starwebserver.se/shops/sollex-se/files/cache/8-types-of-utility-blades-guide-sollex-blog_medium.webp?_=1693568060)