Choosing the right industrial blade

Selecting the correct industrial blade is not about choosing the hardest steel or the most advanced coating.

Cutting performance is created by 3 interdependent factors: the correct blade design and geometry for the application, the right base material, and a coating applied only when it delivers measurable benefits.

At Sollex, blades are engineered by defining the cutting geometry first, selecting the appropriate steel grade or material second, and applying a coating only when it improves performance. This structured approach ensures stable cutting, predictable results, and optimized blade lifetime in material production and converting.

Blade design, geometry and shape

The absolute first step in cutting any type of material is to determine the basic design of the blade, which defines how the cutting blade performs and what results are supposed to be expected. Thickness, edge geometry, bevel type, grinding method, and cutting angle all directly influence cutting force, edge stability, and wear.

Design comes first.

No knife material or coating can compensate for incorrect blade design and shape.

Thinner blades require less force and reduce shear in the material, which helps prevent web breaks and improves cut quality. Multi-facet grinding and burr-free edges produce cleaner cuts and distribute wear more evenly across the cutting edge.

Lower cutting force helps prevent web breaks, edge tearing, and material distortion, particularly when slitting elastic or sensitive films. In many applications, reducing blade thickness alone can significantly improve cut quality and process stability.

A cutting angle of approximately 45 degrees is commonly used to reduce friction at the cutting edge, lower heat generation, and improve edge penetration. This slicing motion allows the blade to separate the material more efficiently and with greater control.

When blade geometry and cutting angle are correctly matched, cutting resistance is reduced before material selection or coating is even considered. This improves process stability and extends blade lifetime in continuous production.

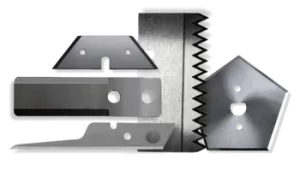

Blade design by application area

The shape and design of industrial knives depend on the area of application, the material being processed, and the cutting method used. Different cutting principles require different blade geometries to achieve stable and predictable results.

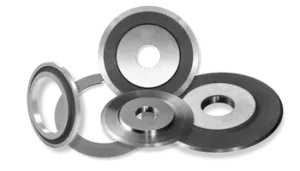

Machine knives for flexible packaging

Circular slitter knives, score rotary knives, toothed and serrated machine knives, pointed knives, perforating blades, crush cutters, tungsten carbide slitting knives, and top and bottom knives for shear cutting applications.

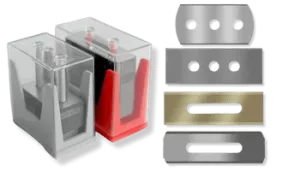

Industrial razor blades for film and foil

Slotted slitter razor blades with straight or rounded corners, industrial razor blades with three holes, injector blades, slitter-rewinder blades, coated razor blades, and solid tungsten carbide razor blades for demanding slitting conditions.

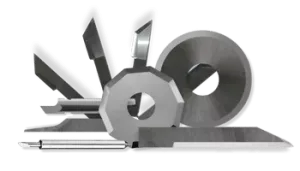

Knives for plastic recycling

Granulator knives, pelletizer die-face cutter blades, and other heavy-duty cutting tools designed for continuous operation and abrasive recycled materials.

Plotter knives and blades for CNC digital cutting systems

Kiss-cut knives, drag knives, oscillating knives, routing bits, and blades for vinyl, labels, and technical materials processed on digital cutting tables.

Customized cutting solutions

Sollex develops customized machine knives and industrial blades based on customer drawings or specific application requirements. Our engineers work closely with production teams to design, develop, and manufacture blades optimized for the intended cutting process.

Steel grade and base material

Once the blade geometry is defined, the base material determines sharpness, toughness, wear resistance, and heat behaviour.

Carbon steel offers maximum sharpness and is often used for clean materials where edge acuity is critical. Stainless steel is chosen when corrosion resistance is required. Tool steels such as D2 and HSS-M2 provide a balance between hardness and toughness and are widely used in industrial slitting applications.

For highly abrasive materials or extreme production conditions, Sollex supplies blades made from solid tungsten carbide or solid ceramic. These materials deliver exceptional wear resistance and durability but require correct handling and application matching.

Material selection sets the baseline performance of the blade and defines whether a coating is beneficial or unnecessary.

Carbon steel · Stainless steel · Tool steel · Tungsten carbide · Ceramic

Blade coatings for performance optimisation

Blade coatings are applied to optimize performance. When used correctly, coatings can reduce friction, protect the cutting edge, lower heat generation, and extend blade lifetime.

Titanium nitride coatings improve surface hardness and reduce dust in general slitting applications. Ceramic coatings protect the cutting edge when processing materials with abrasive additives. Zero-friction coatings minimize resistance and heat in high-speed cutting of thin films. Full ceramic coatings provide maximum protection in extremely demanding applications.

Titanium

Titanium (TiN) coated blades for optimal slitting performance. Gold colored edge. Low friction which gives less dust. Competitive durability and performance. FDA-approved.

Material to cut: Plastic film and foil with few additives

Ceramic

Ceramic coating with black color and fine grain structure. Protects the edge optimally when cutting plastic film with additives such as chalk or titanium. FDA and EC approved for contact with food. High durability and performance.

Material to cut: White plastics with additives

Zero-friction

Zero-friction coating with grey color and extremely fine grain structure. This coating gives minimal friction, which is optimal for high speed cutting such as thin stretched film. FDA and EC approved for contact with food. High durability and performance.

Material to cut: Thin stretch film

Full ceramic

Full ceramic coated blade where the sides of the blade are also coated. The coating is FDA and EC approved for coming into contact with food. Gives an extreme durability when cutting in materials with very grueling additives.

Material to cut: Plastic film with additives, multilayer