Cutting Methods in Cardboard Production

About cutting techniques and knives for paper and cardboard production

Also read another article on a similar topic on our blog " Problems and Solutions when Cutting Honeycomb Cardboard"

Content:

- Cardboard and paperboard packaging types

- Types of paper and cardboard cutting

- Cutting with slitting blade

- Crush cutting with circular knife

- Shear cutting with circular blades

- Chopping

- Cutting on a roll Slitter rewinder machine

- Digital cutting

- Die-cutting and creasing

Industrial cutting methods of cardboard, paper, and paperboard packaging are the subject of this white paper. Focus will be on cutting techniques and knives that are used in the production of paper and cardboard products.

Paper, paperboard and cardboard packaging is an environmentally friendly type of modern packaging and occupies a leading position among all types of packaging. Analyses of the paper and paperboard market show that printing paper, packaging paper and paperboard are the most mass-produced products and are continuously expanding worldwide.

According to analyst firm Mordor Intelligence's "Paper Packaging Market - Growth, Trends, Covid-19 Impact, and Forecasts (2023 - 2028)" [1], the global paper and paperboard packaging market will be worth more than $ 320 billion in 2021 and is expected to grow at a CAGR of 4%. This report states that the major factors driving the growth of the paper and paperboard packaging market are the growing demand for paperboard packaging boxes in the healthcare industry, increasing awareness about the sustainability of packaging materials, the introduction of eco-friendly packaging, and the increasing use of paper-based packaging in the food industry.

The major manufacturers operating in the paper and paperboard packaging market are: Stora Enso, Smurfit Kappa, Svenska Cellulosa Aktiebolaget SCA, Cascades inc., DS Smith, Fedrigoni S.P.A., Atlantic Packaging, International Paper, Mondi, Nippon Paper Industries Co., Ltd., Amcor plc, METSÄ GROUP, Georgia-Pacific, Oji Holdings Corporation, Mayr-Melnhof Karton AG and many others.

The major manufacturers operating in the paper and paperboard packaging market are: Stora Enso, Smurfit Kappa, Svenska Cellulosa Aktiebolaget SCA, Cascades inc., DS Smith, Fedrigoni S.P.A., Atlantic Packaging, International Paper, Mondi, Nippon Paper Industries Co., Ltd., Amcor plc, METSÄ GROUP, Georgia-Pacific, Oji Holdings Corporation, Mayr-Melnhof Karton AG and many others.

We will take a closer look at the packaging cardboard, tell about its variety and methods of cutting in its production.

Cardboard and Paperboard Packaging Types

Cardboard and paper packaging can be divided into the following categories according to their structural characteristics and type of material: corrugated cardboard boxes, solid glued cardboard boxes, cardboard trays, cardboard drums and trays, cardboard inserts, paper sacks, paper cast containers, cardboard pallets, cardboard containers, gaskets, buffers, dividers, etc.

Cardboard can be classified by application:

- Printing

- Packaging and container board

- Design and interior

Type of cardboard | Description |

Corrugated paper and cardboard | Cardboard intended for production of consumer and transport packaging. Types: Single face, single wall (double face), double wall, triple wall cardboard. Standard corrugations are designated as A, C, B, E and F, in descending order of the pitch and the height of the corrugations. |

Solid glued containerboard | This type of cardboard is a multi-ply material, consisting of two or more flat layers of cardboard glued together. It is mainly used in the manufacture of crates, grids and dividers. |

Polymer-coated paper and cardboard | Polymer-coated paper and cardboard are cellulose composite materials consisting of a base of paper or paperboard coated with synthetic polymers. These coated materials are used for packaging and preserving food, technical products, and various chemical, medicinal, etc. substances. Types:

|

We will take a closer look at the packaging cardboard, tell about its variety and methods of cutting in its production.

Types of Paper and Cardboard Cutting

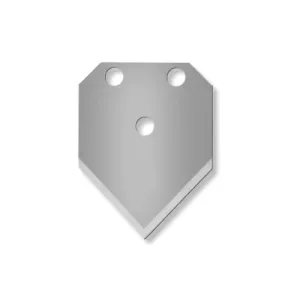

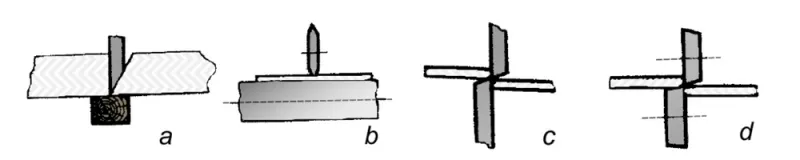

Cardboard cutting is a popular service that uses special cutting machines: Cutters and Slitters. The four types of knife cutting are considered: crush cutting with a slitting blade (a); crush cutting with a circular blade (b); crush cutting with flat blades (c); shear cutting with circular blades (d).

Paper and Cardboard Cutting with Slitting Blade

The blade, moving downwards, cuts paper or cardboard in its lower position into the backing. The backing is made of hardwood, caprone or special materials. The material is separated by the force of the knife edge in the cutting plane. The required cutting force depends on the height and length of the cut, the type of paper or cardboard, and the angle of the knife sharpening.

The cutting part of the knife is made of wear-resistant chrome vanadium steel. The blade sharpening angle is usually 19-22 degrees. A sharper blade (with a lower sharpening angle) reduces the cutting force required, but the blade edge becomes dull or pitted more quickly. A duller edge (with an increased sharpening angle) requires more cutting force, but will last longer. Accordingly, blades with a smaller sharpening angle are used for cutting soft materials, and blades with a larger sharpening angle are used for cutting hard materials.

The knife can move either vertically - parallel or in a compound (sabre) motion. The first type of movement is characterized by the cutting knife moving vertically from top to bottom. When the knife comes into contact with the web material, an impact occurs, as a result of which the material is deflected and the cutting force is at its maximum at the beginning and end of the process. The above reasons explain why this type of knife movement is rarely used in modern paper cutting machines. It is used when cutting paper and board as single sheets or for particularly elastic or hard materials.

In a compound (sabre) movement, the knife starts the cut in an inclined position relative to the horizontal base plane. The blade then gradually cuts into the material, reducing the angle of inclination. Only at the end of the stroke does the blade return to a horizontal position. The blade tilt angle at the beginning of the process is 1 to 40 degrees. Smooth penetration of the material, lower cutting force and a precise and clean cut are the advantages of this blade movement. All modern paper cutting machines are equipped with a sabre blade motion, which is universally applicable for cutting through paper stacks. To prevent the paper stack from bending and shifting during cutting, a pressure beam is used.

Paper and Cardboard Crush Cutting with Circular Knife

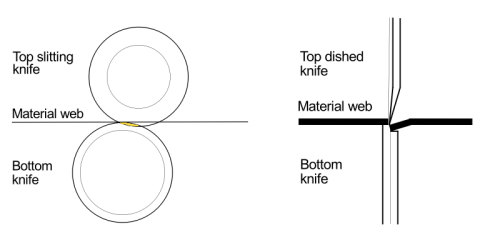

This cutting process is performed by a rotating disk-sharpened knife on a special support shaft. The circular blade is driven in rotation by the friction between the blade and the moving web being cut. The radius of the disk blade depends on the thickness of the material being cut and the angle at which the blade is set relative to the plane of the material. This angle does not exceed 150 degrees. This type of cutting is used mainly for single layer material and also in some types of slitting machines.

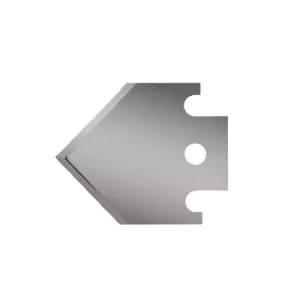

Paper and Cardboard Shear Cutting with Circular Blades

The rotary movement of the knife provides simultaneous cutting and web movement. With continuous material feed, the frictional force increases compared to cutting with flat knives.

Dished knives are used for this type of cutting. The grinding angle of the top knife affects the cutting quality of the material and the strength properties of the blades. In theory, depending on the hardness of the steel, the cutting angle should be as high as possible (close to 87 degrees). In practice, and to reduce frictional force, it is better to keep the cutting angle close to 50 degrees. If the cutting angle exceeds 50 degrees, excessive blade wear or chipping of the cutting edge will occur. Constant attention must be paid to timely sharpening, because in addition to the rotary motion, the knives can also hit their sides and become dull before their time. Rotating circular knives, which operate on the principle of scissors, are widely used in paper cutting and slitting machines.

Dished knives are used for this type of cutting. The grinding angle of the top knife affects the cutting quality of the material and the strength properties of the blades. In theory, depending on the hardness of the steel, the cutting angle should be as high as possible (close to 87 degrees). In practice, and to reduce frictional force, it is better to keep the cutting angle close to 50 degrees. If the cutting angle exceeds 50 degrees, excessive blade wear or chipping of the cutting edge will occur. Constant attention must be paid to timely sharpening, because in addition to the rotary motion, the knives can also hit their sides and become dull before their time. Rotating circular knives, which operate on the principle of scissors, are widely used in paper cutting and slitting machines.

Paper and Cardboard Cutting by Chopping

This particular type of cutting is performed by the impact of a knife. It is used in the production of soft paper packaging (paper sacks, bags, boxes, etc.). The paper web is cut between a toothed knife and a smooth knife, which are offset by a small distance. The result is a wavy or jagged cut of the web.

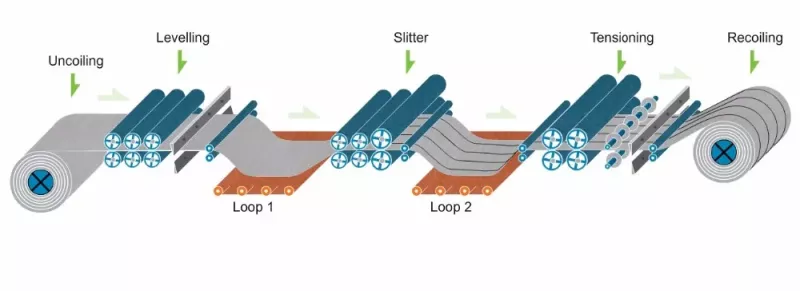

Paper and Cardboard Cutting on a Roll Slitting Rewinding Machine

In recent years, the demand for paper roll slitter rewinder has increased due to the rapid development of the packaging industry, labels and flexible plastic packaging.

Roll slitter rewinders are used for longitudinal cutting of paper and board. The need for different roll sizes (from 8-10 mm to 1m and more) with different material densities, from fine paper to medium-density board, led to the creation of slitting machines of different designs and capacities. Slitting machines for reels belong to the category of high speed machines with a cutting speed of up to 200 meters per minute.

The cutting of paper and cardboard on reels consists of the following steps: paper or cardboard reels are fixed and placed on an unwinding stand which is equipped with a device for adjusting the position of the reel. The lower knives are positioned at intervals equal to the specified width of the paper strip. Then the top knives are mounted close to the bottom knives and the paper strip is fed to the cutting and winding section of the machine. To ensure that the paper web is well tensioned, a braking device is pressed on the stand. After the roll width has been checked and the machine is ready to start, it is started at the lowest speed and gradually increased. The knife tool of the winders consists of upper and lower knives mounted on two parallel shafts. The knives work like a rotary shear. The top knives are circular knives and the bottom knives are disc-shaped . A tight fit of the knives in the working position is ensured by dampers in the form of spiral spring rings on the upper disc knives.

One of the most important conditions for producing quality spools is tight winding. A tightly wound roll is stiff, withstands transportation well, and unwinds smoothly (without jerking) when reused. To achieve this, most slitters and rewinders have pressure rollers that wind the paper very tightly. Considering the high speed of slitting machines and the frequent need to cut narrow, weak tear-off strips, most types of these machines are equipped with speed variators for smooth, gradual increase of the machine speed.

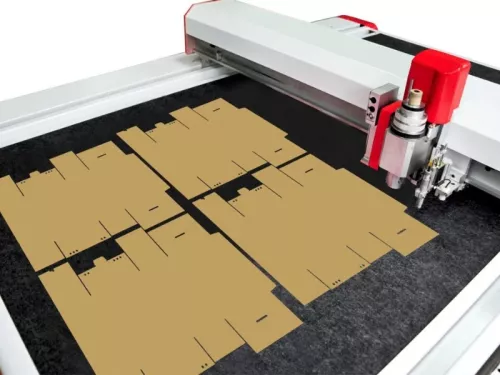

Plotter Cutting of Corrugated Cardboard

Digital cutting machines are precise enough to process cardboard with high quality. Plotter cutting of corrugated board on digital cutting machines allows economical use of material to process products with high accuracy. The knives of the cutting plotter leave an even mark without deformation. The machine can cut from one sheet up to several dozen, which allows the creation and design of customized products.

Digital cutting machines are precise enough to process cardboard with high quality. Plotter cutting of corrugated board on digital cutting machines allows economical use of material to process products with high accuracy. The knives of the cutting plotter leave an even mark without deformation. The machine can cut from one sheet up to several dozen, which allows the creation and design of customized products.

To produce durable corrugated board, the following methods are used:

- Cutting with a CNC plotter runs perpendicular to the flutes. During processing, the cushioning properties of the product are demonstrated. The low stiffness of the corrugation allows the production of decorative elements.

- Cutting with a plotter cutter along the flutes. This has a positive effect on strength, as the stiffening ribs are not damaged during processing. Depending on the number of layers, corrugated board is used to make substrates or boxes for transporting goods.

The cardboard is cut with sharp plotter knives mounted in a CNC plotter machine. The machine, in contrast to the mechanical method of processing, performs contour cutting based on the set parameters. The software allows the user to control the quality and depth of the cut. As a result, corrugated board sheets get a clean cut without burning or tearing the cutting edges. Accuracy of panel cutting is achieved by vacuum fixing of the material.

The software and the possibility to set the exact cutting dimensions allow you to obtain shapes of any complexity. Such cutting technology is suitable for the production of packaging, shelves, large and small figures, 3D constructions, and pallets.

Die-cutting and Creasing of Cardboard

Die-cutting is the process of cutting a product out of a cardboard sheet using shaped knives of a certain configuration. This cutting method is used on die-cutters to produce labels, cardboard boxes, corrugated packaging, and other packaging. The punching process, with the help of a die cutter, allows you to cut a shape out of the packaging or printed product. Stamping presses are used to die-cut the outer contour of cardboard, paper, or plastic. Die-cutting can be performed on rotary die-cutters or die-cutting on individual sheets of cardboard using a flat die.

Die-cutting is the process of cutting a product out of a cardboard sheet using shaped knives of a certain configuration. This cutting method is used on die-cutters to produce labels, cardboard boxes, corrugated packaging, and other packaging. The punching process, with the help of a die cutter, allows you to cut a shape out of the packaging or printed product. Stamping presses are used to die-cut the outer contour of cardboard, paper, or plastic. Die-cutting can be performed on rotary die-cutters or die-cutting on individual sheets of cardboard using a flat die.

This method is a common method of producing cardboard boxes or packages, where you need to cut a complex shape and fold lines.

Common die-cutting options are steel rule die-cutting, compound dies, rotary die-cutting, rotary press die-cutting, slitting, kiss cutting.

In addition to cutting, there are also processes such as

- Scoring: Instead of cutting all the way through the material, scoring leaves an impression or partial cut at a single stress point.

- Creasing: Similar to scoring, the die creates a crease in the packaging material. Unlike scoring, creasing allows the material to bend inward by having two parallel points of stress. Greater flexibility of the material is achieved by having two stress points.

- Perforating: Perforation is the punching of a line of holes along the length of the design material. The design can be easily separated along the perforated lines rather than being separated from the material itself.

FAQ

Q: What types of knives are most commonly used for cutting cardboard?

A: Flat cutting knives, slitting blades, and circular rotary knives are all used depending on the material and cutting method. The right choice depends on the cardboard type and whether the operation requires slitting, shear cutting, chopping, or die cutting.

Q: When should I use a slitting blade instead of a rotary knife?

A: Slitting blades work well for continuous straight cuts and simple cardboard types. Rotary knives or circular shear knives are better when smoother edges and controlled cuts are needed, especially for thicker, laminated, or coated cardboard.

Q: How does the sharpening angle affect cutting performance and blade life?

A: A smaller sharpening angle creates a sharper edge, which requires less cutting force and provides clean cuts, but it dulls faster. A wider angle increases durability but needs more pressure and may slightly deform the edge of the cardboard.

Q: What kind of cutting motion gives the best result on cardboard?

A: A shear or rotary motion is generally preferred. Unlike vertical cutting, which can crush or tear fibers, a shear motion slices the material cleanly and evenly, reducing deformation and edge defects.

Q: What happens if a knife is too sharp or too dull?

A: A too sharp knife can wear out quickly or chip, which results in irregular edges. A dull knife generates friction and pressure that can crush or delaminate the cardboard instead of cutting it cleanly.

Q: How can I choose the best cutting method for different cardboard grades?

A: Thin or single wall cardboard can be cut effectively with straight or slitting blades. For multilayer, laminated, or coated materials, rotary shear knives or circular blades provide better results with cleaner edges and more consistent quality.

Q: What maintenance practices help maintain cutting quality over time?

A: Inspect blades regularly, clean them carefully, and replace or sharpen when wear appears. Check alignment, knife holders, and cutting motion to keep cuts accurate and consistent.

Q: How often should knives be inspected or replaced?

A: It depends on production speed, material type, and abrasiveness. Knives should be checked frequently for signs of dullness, chipping, or buildup to prevent poor edge quality and ensure smooth, efficient cutting.