Guide to Avoiding Cuts and Lacerations at Work

What are the main causes of knife related injuries at the workplace

More and more companies are investing in safety knives due to: knife accidents, injured workers, and financial costs.

Content:

- Reasons behind accidental knife injuries at work

- About safety knives

- Measures that may be implemented to increase workplace safety

- Why your company should provide employees with safe knives

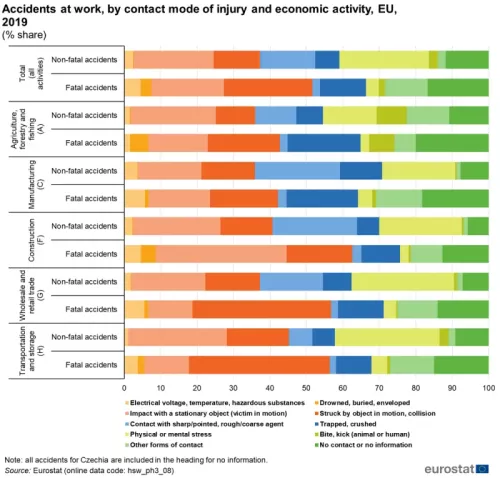

The article "Accidents at Work - Statistics on Causes and Circumstances" by Eurostat (https://ec.europa.eu/eurostat/statistics-explained/index.php), the statistical office of the European Union presents statistics on non-fatal accidents and their causes i in the EU 2019. In 2019, one of the most common types of nonfatal accidents in the EU was contact with a sharp/pointed or rough/coarse objects (15.2%).

According to 2019 data from the U.S. Bureau of Labor Statistics (https://www.bls.gov/), accidents including cuts, lacerations and punctures account for about nine incidents per 10,000 full-time workers. These injuries are also among the most common types of injuries that cause workers and independent contractors to miss the time on the job, averaging four days.

Reasons behind accidental knife injuries at work

Workplace accidents frequently include cutting instruments, especially knives. The most common workplace knife injuries are:

- Cuts to the other hand while cutting

- Cuts to the working hand if it has slipped off the handle

- The knife has fallen with the blade down

- Cuts in the direction of self

- A chipping of the knife blade

- Cuts in the hand or fingers if the knife is not properly stored in the workplace

You can lessen the danger of harm by using safety knives and taking other precautions.

What is a safety knife

A safety knife is a type of knife with a unique or uncommon design that is mostly used for securely opening packing and boxes. The goal of safety knives is to lower the possibility of cutting accidents at work. In contrast to using a standard utility knife, most safety knives have a concealed or automatically retractable blade that retracts when the user presses a slider. When the user releases the slider, the blade retracts automatically, protecting the worker from unintentional cuts.

In today's workplace, safety knives are a standard item, especially for employees who work in areas like shipping and receiving, warehousing, and logistics where knives and cutters are used regularly. Safety knives and cutters are useful for a variety of tasks, including cutting shrink wrap, tape, strapping material, and opening different kinds of packaging.

Read more about safety knife types in our other article "6 types of safety knives".

What additional measures can be taken to improve workplace safety?

Select the appropriate cutting instruments for your staff

Selecting the right knife for a certain task is essential. It is feasible to utilize many knives for various activities in one workspace. Work knives come in a variety of forms, so give your staff the ones that best suit their methods of operation.

Selecting the right knife for a certain task is essential. It is feasible to utilize many knives for various activities in one workspace. Work knives come in a variety of forms, so give your staff the ones that best suit their methods of operation.

Here you can read how to choose the right safety knife for your needs and applications.

Purchase high-quality blades and knives

Avoid purchasing inexpensive, subpar safety knives since they can rust, shatter after heavy use, and get dull rapidly.

Keep extra blades and knives on hand at all times

Changing blunt safety knife blades on time is the primary guideline for safe knife handling! Since the user must apply more pressure and power to cut the material, a knife with a duller blade is less safe. So keep a supply of new blades so that your employees can replace the blunt blade when needed.

Before using the knife, check it

Please remind employees to thoroughly inspect the knife before using it. Avoid using dull blades and damaged knives. Verify that the tool is operating as intended and that the edge is both sharp and in excellent shape. Using a defective blade, whether it is dull or chipped, can easily result in significant harm. When used, a damaged knife is more likely to break or develop a chip. Stress how crucial it is to inspect the PPE and the blade before each usage.

Proper storage

Knife storage safety is a crucial aspect of worker safety. It's advised to clean the knife after cutting something large and storing it somewhere secure. Knives should never be merely left lying about, as there is a significant danger of harm. Furthermore, it's critical to dispose of dull blades correctly. Have containers with labels on them or buy safety blade boxes specifically made for this use.

Knife storage safety is a crucial aspect of worker safety. It's advised to clean the knife after cutting something large and storing it somewhere secure. Knives should never be merely left lying about, as there is a significant danger of harm. Furthermore, it's critical to dispose of dull blades correctly. Have containers with labels on them or buy safety blade boxes specifically made for this use.

Why your company should provide employees with safe knives

An essential component of workplace safety are safety knives. You may prevent inadvertent product damage caused by box cutters, common hand knives, and snap-off knives, as well as lower the cost of sick leave and production downtime, by switching to safety knives instead of these items.

If you are not sure which type of safety knife is best for your purposes, please contact us and we will be happy to help you.