How to Cut Mineral Wool [GUIDE]

Content:

- About mineral wool insulation material

- How to transport and store

- Best knife and blade to cut mineral wool

- How to cut mineral wool

What is Mineral Wool?

Mineral wool is a form of insulating material created by spinning or pulling molten materials such as rock, basalt, slag, or other hard materials, which are melted at high temperatures and then spun into fibers. The fibers are then bound together with a binder to form a thick mat of insulation material.

Mineral wool is a form of insulating material created by spinning or pulling molten materials such as rock, basalt, slag, or other hard materials, which are melted at high temperatures and then spun into fibers. The fibers are then bound together with a binder to form a thick mat of insulation material.

Mineral wool is classified into the following categories based on its source material:

- Rock wool or basalt wool is made from basalt or other volcanic rocks. It provides great strength, fire resistance, and sound insulation properties. Widely used to insulate facades, roofs, and other buildings that demand great strength and longevity.

- Fiberglass wool is formed of glass waste, sand, soda, and limestone. It is lightweight, flexible, and has outstanding thermal insulation characteristics. Typically utilized in low-load buildings, such as attic, wall, and floor insulation.

- Slag wool is created from blast furnace slag generated during the iron manufacturing process. Less popular owing to brittleness and excessive water absorption. It is mostly employed in industrial settings and buildings.

Mineral wool is a great option for insulation in spaces that are exposed to heat or flames since it is both heat- and fire-resistant. Furthermore, mineral wool does not contribute to the spread of fire since it is non-combustible. Additionally, it resists mold and moisture, which helps to stop the formation of dangerous fungus and bacteria.

How to Transport & Store Mineral Wool Insulation

Transporting and storing mineral wool requires proper handling to prevent damage and ensure that it remains in good condition. Here are some tips to help you transport and store mineral wool:

Transporting and storing mineral wool requires proper handling to prevent damage and ensure that it remains in good condition. Here are some tips to help you transport and store mineral wool:

- Use protective packaging. When transporting mineral wool, use protective packaging such as plastic wrapping or durable boxes to prevent damage during transit.

- Avoid compressing the material. Do not stack heavy items on top of the mineral wool, as this can compress the fibers and reduce its insulating properties.

- Store in a dry place. Store mineral wool in a dry place to prevent moisture damage, which can reduce its effectiveness as insulation. Avoid storing it in damp or humid areas.

- Keep away from sources of ignition. Mineral wool is fire-resistant, but it should still be stored away from sources of ignition such as open flames or heat sources.

- Handle with care. When handling mineral wool, wear protective clothing such as gloves and a dust mask to protect yourself from dust and other small particles.

- Do not store outside. Mineral wool should not be stored outside, as exposure to sunlight and moisture can damage the material.

- Unpack the mineral wool just before starting the insulation.

By following these tips, you can ensure that your mineral wool remains in good condition during transportation and storage, and that it will be effective as insulation when you are ready to use it.

Best Knife to Cut Mineral Wool

Use of ordinary knives or scissors designed for cutting cardboard or other hard materials is not recommended. Serrated bread knives, construction knives, or stationery knives with serrated blades can be used to cut through the thinnest insulation (no thicker than 50 mm). Denser and thicker insulating materials are designed to be cut through using an insulated material knife longer than 250 mm. To cut mineral wool, these specific blades have teeth of varying sizes.

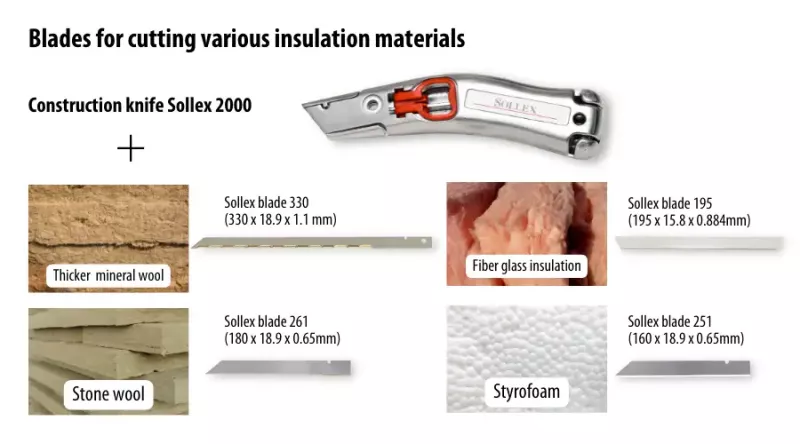

Sollex has just the right blades for cutting a variety of insulation materials.

- Thicker insulation materials. The Sollex blade artnr. 330 is 330 mm long (330 x 18.9 x 1.1 mm) with strong titanium-coated teeth, suitable for cutting thicker insulation. The 1.1 mm thick blade is made of quality steel and provides good durability and excellent cutting properties for the professional user.

- Stone wool.The 180mm long knife artnr 261 is suitable for cutting mineral wool insulation materials and mineral wool slabs. The 0.65 mm thick double-sided blade made of quality steel provides excellent durability for the professional user. The 261 stone wool cutting blade fits the Sollex construction knife (2000). Special holster (300) is recommended for safe storage when the knife is not in use. Suitable for cutting stone wool insulation and stone wool boards. Extra holster black for 251 and 261 (180mm blade) fits this blade knife perfectly.

- Fiberglass. Blade Art. 195 (195 x 15.8 x 0.884mm), which is adapted for use in industrial production and is particularly suitable for cutting glass wool and rubber. Grinding is 33 degrees for optimal fiberglass cutting.

- Foam. Knife blade artnr 251 is 160 mm long (160 x 18.9 x 0.65mm) and is adapted to cut the cellplast, frigolite, and styrofoam, for example, but also other types of insulation. It is made of 0.65mm thick quality steel, double ground, which provides good durability for the professional user. Extra holster black for 251 and 261 (180mm blade) fits this blade knife perfectly.

How to Cut Mineral Wool

The way of cutting the mineral wool depends on the shape of the mineral insulation material web. Rolled insulation is not unrolled before cutting; cut it directly rolled up. Tile-shaped mineral wool is better cut tile by tile. By cutting in this way, you prevent the spread of particles of glass wool or basalt insulation in the room and air, especially since they are dangerous to human health. If you inhale such a fine, spiky dust, it can settle in the lungs and cause serious diseases.

The way of cutting the mineral wool depends on the shape of the mineral insulation material web. Rolled insulation is not unrolled before cutting; cut it directly rolled up. Tile-shaped mineral wool is better cut tile by tile. By cutting in this way, you prevent the spread of particles of glass wool or basalt insulation in the room and air, especially since they are dangerous to human health. If you inhale such a fine, spiky dust, it can settle in the lungs and cause serious diseases.

We offer these tips:

- The cutting tool should be sharpened so that the mineral wool is not split into fibers and there is less "dust."

- When cutting the insulation, leave around 2 cm of mineral wool for the seams to achieve a tight overlay.

- It is best to cut the roll of mineral wool unpacked.

- Unpack and cut each insulating panel individually.

- It is not advisable to cut all of the mineral wool at once.

Additional safety requirements when dealing with mineral wool

To protect the hands, use a protective suit made of thick material that avoids skin contact with mineral wool fibers and discomfort. Wear special gloves with silicone or rubber covering on the palms; special glasses will be required to protect the eyes; and a respirator will protect the respiratory system. Remember to wear a protective helmet or cap on your head when cutting and putting insulation on vertical surfaces

Longitudinal cutting of mineral wool

Mineral wool rolls are cut unpackaged. The roll is put on a firm, flat surface, and the desired length is measured. Marks can be made in three different locations on the roll's circle. To improve precision, the designated cutting locations are taped together. The roll of mineral wool is then sawed as indicated by the markings. The packaging foil can only be removed once the sliced piece has been separated.

Cross cutting the mineral wool

To cut crosswise, unroll the mineral wool and mark both sides. Attach a level bar, such as a ruler, and position a board beneath the insulation material to keep the knife from dulling. Pull the knife alongside the ruler. If you can't cut the material in one motion, cut it multiple times until it's completely cut through. Always keep the blades you use to cut the wool or mineral insulation materials sharp. We recommend cutting the insulation material crosswise. If the mineral wool is in sheets, cut it one at a time.