On-Time Order Shipments & Delivery

2025 - WEEK 50; 100%

On this page you will find Sollex's wide range of high quality coated and uncoated injector blades optimized for cutting a variety of materials. We coat razor blades to protect the blade from abrasion, reduce friction and increase performance and durability. If you are cutting thin stretched film, our Z coating is perfect. For white plastic film (with chalk additive), K-coated injector blades are a smart choice. For really tough films (such as those with titanium additives), Sollex C solid ceramic is recommended.

Worldwide shipping. Orders for the stocked product made before 13.00 are usually shipped the same day. Read more on our Order & Delivery page. If you can't find what you're looking for you're very welcome to get in touch with us at +46 35-157500 or info@sollex.se.

Sollex manufactures injector razor blades for a variety of applications, such as cutting plastic film or foil. The injector-type razor blades from Sollex are sharpened to perfection to give you competitive cutting edge performance. If you want your cutting process to be stable for a long period of time without interruption or reduced performance, then Sollex Injector blades are recommended.

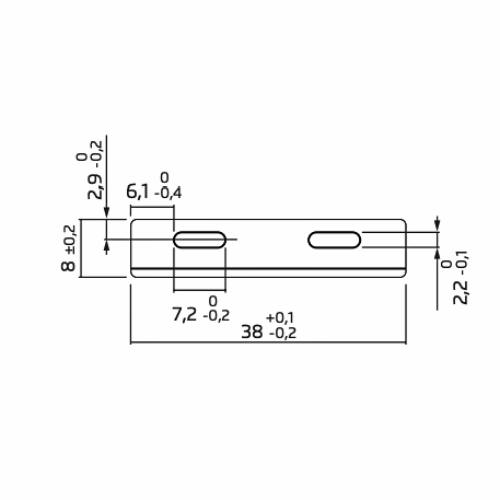

Injector blades are very small razor blades ideal for heavy industrial use. Originally, engineers developed injector blades as razor blades for shaving. The blade has a single cutting edge. Today, injector blades are mostly used for industrial purposes. The size of the blade is quite small 38x8x0.25mm or 1.496"x0.315"x0.01". This means that the Injector razor blade can fit into really small areas of your machines.

Sollex Injector razor blades are packaged on spears. The bulk 642PR Injector Blade contains 1000 pieces per package. They are delivered in packaging that separates the edges from each other. We package our high-performance injector blades in smaller boxes, oil them, wrap them in protective paper, and vacuum seal them. The edges of the injector blades must not touch the packaging.

Sollex Injector razor blades are packaged on spears. The bulk 642PR Injector Blade contains 1000 pieces per package. They are delivered in packaging that separates the edges from each other. We package our high-performance injector blades in smaller boxes, oil them, wrap them in protective paper, and vacuum seal them. The edges of the injector blades must not touch the packaging.

We offer single-edge injector razor blades in various product qualities. Our entry-level quality stainless steel injector blades are suitable for cutting various substrates such as PVC, PET, LLPDE, HDPE, PP, shrink film, stretch film, overwrap, etc. Uncoated Sollex bulk injector blades deliver exceptional performance and are specifically designed and adapted for industrial use. Sollex Stainless Steel Injector Blades are made in the USA from high-quality stainless steel that has been hardened and ground to perfection.

Sollex offers coated industrial injector blades that change the cutting characteristics of the blade. These coated injector blades are durable and ideal for heavy industrial use. To protect the blade from abrasion, reduce friction, and increase performance and durability, we coat injector blades. If you are cutting thin stretch film (e.g. LLDPE) with an automatic or semi-automatic wrapper, our Z coating - 642Z- is perfect. For white plastic film (e.g. poly film with chalk additive), K-coated injector blades - 642K - are a smart choice.

Our coated injector blades in dispensers must be experienced and tested. We coat Sollex injector blades with titanium, ceramic, zero-friction and tungsten carbide.

Our ceramic-coated injector blades are FDA and EC approved, which means they can come into contact with food.

All of our injector blades are designed for extreme performance and durability. An ordinary industrial blade installed in a plastic film cutting machine will typically last 20 minutes. But Sollex solid ceramic (C) injector blades can last months. So the difference is huge. The solid ceramic (C) is self-sharpening. This means that the more it wears, the sharper the Injector Blade becomes. The Sollex 642C Injector Blade gives you extreme performance and durability for tough films and foils.

All of our injector blades are designed for extreme performance and durability. An ordinary industrial blade installed in a plastic film cutting machine will typically last 20 minutes. But Sollex solid ceramic (C) injector blades can last months. So the difference is huge. The solid ceramic (C) is self-sharpening. This means that the more it wears, the sharper the Injector Blade becomes. The Sollex 642C Injector Blade gives you extreme performance and durability for tough films and foils.

Who sells injector razor blades? The simple answer is that you can buy them from Sollex AB in Sweden. Where can I find injector blades? You can order injector razor blades online at sollex website or by ringing or mailing us.

Is performance and durability important for your processes and business? Then the Injector razor blades from Sollex are the right choice for you. Try our injector blades to make sure you find the best blade for your particular cutting process. Browse through our wide range and if you are unsure of which blade to choose drop us a mail or - call us on 00 46 35 - 15 75 00, and we will help you.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.