Blades for Cast Film Extrusion & Web Trimming

Welcome to Sollex, your one-stop destination for high-quality blades designed specifically for plastic film, cardboard and flexible packaging applications. We understand the unique challenges that come with working with plastic films and flexible packaging materials. That's why we have developed a comprehensive collection of industrial blades that deliver exceptional performance, precision, and durability. Whether you need blades for slitting cardboard rolls, perforating plastic film, or cutting PCR plastic films, our products are engineered to meet your exact requirements.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page or contact us at order@sollex.se.

For flexible packaging and plastic film manufacturers, it is critical to have a reliable supplier of industrial knives and blades for a continuous production flow. Sollex can be your one-stop-shop supplier that will supply you with high-quality industrial knives and blades. We manufacture and solve your production problems related to cutting and converting flexible packaging materials from 1927.

For flexible packaging and plastic film manufacturers, it is critical to have a reliable supplier of industrial knives and blades for a continuous production flow. Sollex can be your one-stop-shop supplier that will supply you with high-quality industrial knives and blades. We manufacture and solve your production problems related to cutting and converting flexible packaging materials from 1927.

Whether you are looking for circular paper slitting knives that cut paper and cardboard on rolls, knives for print packaging, 3-hole ceramic-coated blades for cutting plastic film with PCR or PIR, ultra precision knives with an extreme Ra 0.01 tolerance for application in Med tech, or blades for pelletizing and recycling industry, we can provide it all to your order.

Sollex ensures that each blade is made from the highest quality materials so that they last as long as possible. But just as importantly, we have some of the most affordable pricing on knives and blades for production and conversion packaging lines that you can find among machine knife suppliers.

Flexible packaging is defined as packaging designed to hold products, goods, solids, liquids, pastes, creams, or powders that is flexible when applied to it and the shape can be easily changed.

Various materials are used to produce flexible packaging, but mainly we can say plastic polymers polystyrene PS, polyethylene (PE, LDPE, HDPE, LLDPE), polypropylene PP in the form of plastic foil or thermoforming films, nylon, aluminum foil, cardboard, paperboard, paper, rubber and others.

Razor Slitting Blades | Slotted slitter blades, industrial razor blades with 3 holes, injector blades are meant for slitting and converting mainly of plastic film and foil, aluminum foil, paper and thin carton used for flexible packaging manufacturing. Learn more about razor slitting of flexible materials in our blog |

Top & Bottom Knives for Shear Cutting | Shear slitting can be used on a wide variety of materials including film, paper, laminates, textiles, foils and more. Top knife usually has a dished design and works in pairs with the bottom knife. Learn more about shear cutting of flexible materials in our blog |

Circular Slitting Blades | Rotary slitting bladesare often used in the flexible packaging industry for longitudinal cutting - slitting - of cardboard, paper, aluminum foil, film on converters and rewinders. |

Crush Cutter Knives | Crush cut knives are machine knives used in crush or score cutting. These industrial knives are also referred to as Crushing knife, Perforating knife, Crush cut perf knife, Score / crush cutter, Score cut knives, Circular Crush / Score knife. Crush cutters are available in D2, HSS-M2, Tungsten Carbide. |

Perforating Knives | Perforating is often carried out in the production of flexible packaging, such as plastic bags, cardboard packaging, and wherever the user will need to make an impact to tear off or change the shape of the package. Perforating knives a whole lot depending on the perforation pattern, the number of teeth, material |

The table above lists only some of the industrial blades used in one way or another for the production of flexible packaging and plastic film.

Industrial razor blades are used for razor slitting in slitter or converter machinery. These blades are thin, straight slitting blades optimized for cutting narrow strips of material. Industrial razor blades are used in various manufacturing and processing industries to cut through different materials such as paper, plastic film and foil, and other soft materials.

We can say with confidence that you won't find such a range of Industrial Razor Blades for Flexible Packaging Slitting and Converting as Sollex's anywhere else.

For flexible packaging manufacturers, we offer a number of different industrial blades: Slotted slitter blades, 3-hole industrial razor blades, Injector blades.

1. Slotted slitter blades. They come with straight or rounded corners. Thickness of such slitter blades are 0.40 mm and 0.20mm. Standard blade size is 57x19x0.40mm.

2. 3-hole industrial razor blades. Such slitting blades also come with straight and rounded corners. The blade sizes are as follows:

3. Injector blades. These are small industrial blades, usually sized 38x8x0.25mm. They have 2 holes for mounting in the slitter machine.

Industrial razor blades are usually made of high-quality steel or other durable materials, such as tungsten carbide, ceramic, allowing them to withstand heavy use and produce precise cuts for long periods of time.

Contact our support at order@sollex.se and we'll help you find the right blade, material, thickness and additional coating for your application.

Customized knives for the packaging industry are quite common and in demand. Sollex manufactures such machine knives for its customers by selecting and manufacturing the right cutting solutions or adapting existing knives to customer needs.

We can offer you these customization solutions for industrial machine knives and blades for packaging industry:

1. Manufacturing and refining industrial blades to suit your application and material. Also manufacture packaging industry blades according to your drawing or OEM

2. Coating industrial knives and blades with ceramic, titanium, and other additional and enhanced cutting properties.

3. Manufacturing machine knives and blades of high quality materials, proven by time and experience. We produce our knives from German and Swedish steel, and we have proven suppliers of other raw materials used in the production of knives from carbide, bi-metal, and other alloys.

4. Mirror polishing of circular cutting knives will surprise you with excellent results. Read more about this technique to increase performance and cutting quality of slitter knives in our blog. We will mirror polish industrial knives and blades when you order from us.

Plastic recycling is usually one of the processes accompanying the production of plastic film or flexible packaging. All defective plastic products can and should be recycled into Post-Industrial Resin and produced again into plastic film or flexible packaging.

Post-Industrial Resin (PIR) is a term used to describe plastic resin that is recycled from industrial waste streams. It refers to plastic waste generated during the manufacturing process or other industrial operations. This waste is collected, processed, and recycled into new plastic products or incorporated into other manufacturing processes. Polyethylene (PE), high-density polyethylene (HDPE), polypropylene (PP) or polystyrene (PS) are the types of plastic waste that usually get regranulated.

The use of PIR plastic helps reduce waste and the demand for virgin plastic materials. It promotes sustainable practices by diverting industrial waste from landfills and supporting the circular economy.

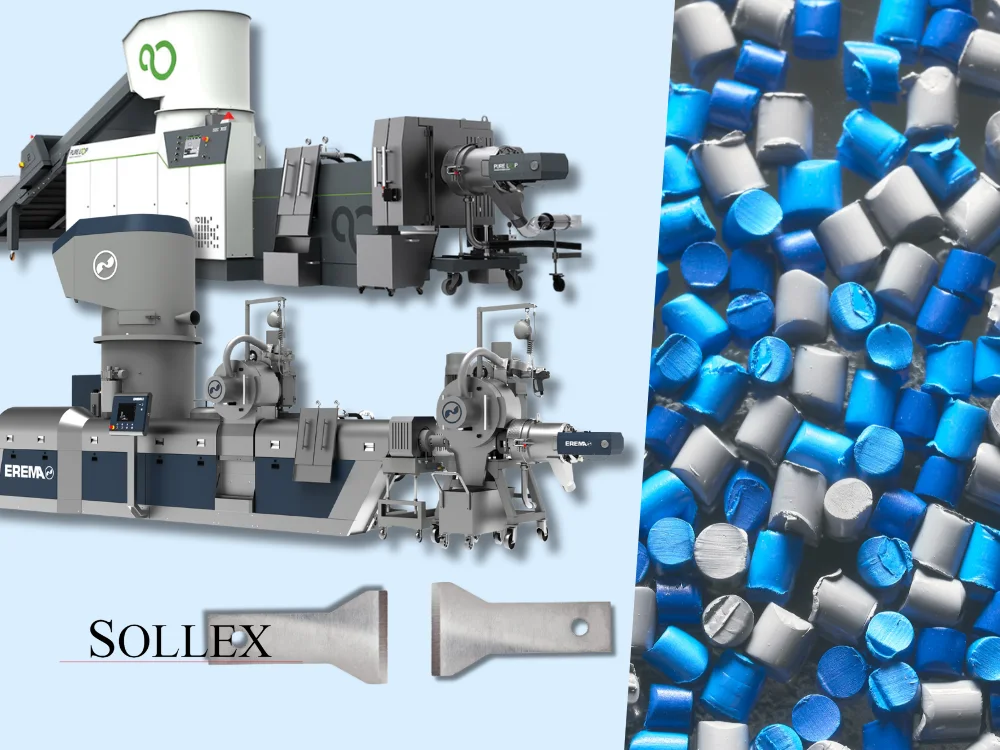

Pelletizer / pelletizing blades are specially designed blades used in the recycling process to cut extruded plastic strands into pellets or also called resin, granulate, regranulate, PIR, PCR. Pelletizing occurs after shredding waste plastic or film into small pellets or pieces, which are then melted and molded into new plastic products or blown into plastic film.

The knives and blades for plastics recycling are also known as: pelletizer blades, pelletizing blades, pellet cutting blades, pelletizer knives, pelletizing cutter blades, die face cutter blades, granulating knives, die face blades, die face knives, hot die face cutter blades, densifier knives, granulator cutter knives.

Sollex manufactures all of the above-mentioned knife types used in plastic recycling on such plastic recycling systems manufactured by Erema, Munchy, Gala, NGR, Weima or others. Learn more about blades for industrial plastic recycling machines in our blog.

Only some of the pelletizing knives for plastics recycling machines are shown on this page. You are always welcome to contact our support and we will provide you with the full range of blades and knives for the plastic producing and converting industry.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

2025 - WEEK 48; 98%

![Sollex awarded with AAA rating by Bisnode [2025] Sollex has been awarded AAA credit rating 2025 by Bisnode - Blog](https://cdn.starwebserver.se/shops/sollex-se/files/cache/johan-falk-sollex-vd-ceo-aaa-business-awards-2025-1_grande.webp?_=1763540059)

Sollex has been awarded the Star Business Awards 2024 and 2025

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.