Industrial Blades to Cut EPDM & Silicone Cords [Customer case]

"The thinner the blade, the finer the cut. The thinner the blade, the less force is needed to cut... "

Sollex will be glad to help you find knives, knife blades or industrial razor blades for your needs. We will introduce a new series on the blog and publish useful cases that can help other readers and customers. Email order@sollex.se or call 035-15 75 00 and we'll advise you on any sharp questions you might have.

____________________

An innovative customer is developing a cutting machine (similar to a guillotine) for EPDM as well as silicone cord with a diameter of 6mm. The question for Sollex is whether there is an optimal industrial knife blade to use in the new design. The customer's priority was the best possible durability and that the razor blade is FDA approved.

A little more about the material to be cut.

"The strings that we will mainly be cutting in our new design:

- Silicone dia 6mm, 70 Shore A, FDA-approved (red) - no other additives

- EPDM, dia 6mm, 70 Shore A, FDA-approved (white) - no other additives

- EPDM, dia 6mm, 90 Shore A, FDA-approved (white) - no other additives"

Thus the questions were:

- Can you recommend a 3-hole industrial razor blade to cut EPDM- and silicone cords?

- Is there a drawing with hole spacing/hole dimensions for measuring our fastener?

- Can we get some samples to test cutting the materials?

Can you recommend a 3-hole industrial razor blade to cut EPDM- and silicone cords?

Sollex has many knives for industries. These are divided into different thicknesses and different qualities (with regard to performance and durability). Step one is to consider which thickness works best for the application. Sollex offers industrial blades of high quality in thicknesses of 0.13mm, 0.20mm, 0.30mm, 0.40mm and 0.68mm. We can manufacture and offer both thinner and thicker knife blades. We also have a lot of 3-hole blades with rounded corners.

The thinner a razor blade is, the finer the cut you get. The thinner the knife, the less force is needed for the cut. So for an optimal cut you need to use as thin knife as possible. But the blade should still be durable and not shear or vibrate. This is remedied by having a thicker blade.

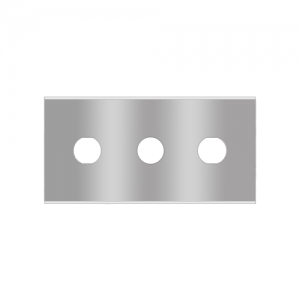

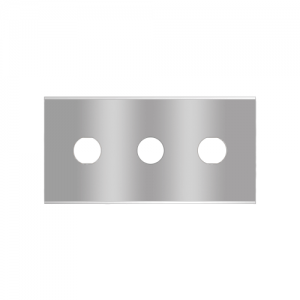

Our general recommendation for cutting EPDM, silicone cord and other materials is to start with the 2-013-R straight 3-hole blade SS (43x22x0.13mm). Does it give a good cut? Will it be as good with the 2-020-R? If not, increase the thickness to 2-030-R. With the right thickness of the 3-hole blade, the next question is what can be done to extend the durability. Some different techniques for longer durability are coating of the cutting edges, whole coated blade and manufacture the blade from different steel materials.

Here is a link to the different materials Sollex manufactures industrial razor blades in - Sollex product qualities. These 3 hole knives are suitable for cutting different materials. In this particular case we recommend the 2-020-Z for cutting EPDM and silicone cord with a thickness of 6 mm.

Is there a drawing with hole spacing/hole dimensions for measuring our fastener?

Sollex has drawings and .stp files of all products which we are happy to share with specific customers. Contact us at order@sollex.se and we will send you the correct drawing.

Can we get some samples for test cutting the material?

It is usually appreciated and interesting for Sollex customers to test a few different knife blade variants. Therefore, we are happy to offer customers and potential new customers to test our different products by sending a sample. Please contact order@sollex.se and we will see how we can help you.

![Sollex tipsar om industrirakblad för att skära EPDM- och silikonsnören [Kundcase]](https://cdn.starwebserver.se/shops/sollex-se/files/cache/industrirakblad-for-att-skara-epdm-och-silikonsnoren-sollex-svarar-pa-kundfragor_medium.jpg?_=1638439052)