Slitting of Flexible Packaging containing Calcium Carbonate

This article is about slitting white plastic film. Cutting film with calcium carbonate as an additive is a tough job to do. The calcium carbonate changes the cutting properties compared to virgin film. For industrial slitting of films containing calcium carbonate, such as chalk, limestone or marble, special blades are required.

Getting to Know Calcium Carbonate Material

Calcium Carbonate is added to plastic materials for two reasons: to reduce the amount of plastic and to change its properties. The mechanical properties of the plastic are very different when calcium carbonate is added. During extrusion, the Calcium Carbonate causes the plastic to foam and allows more air to enter. Additionally, the final product gets improved impact strength.

What is Calcium Carbonate?

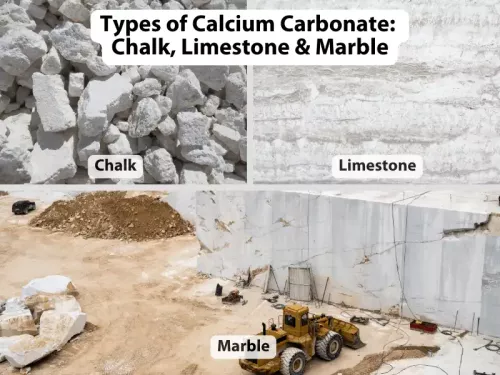

Calcium carbonate is a chemical compound with the chemical formula CaCO3. It is one of the most abundant minerals on Earth. It is found in the shells of marine organisms such as oysters, clams, and corals. Calcium carbonate is a substance found commonly in three natural forms: chalk, limestone, and marble, formed from ancient marine deposits. Chalk is a soft rock that forms when calcium carbonate sedimentary rocks are not compacted enough and remain in a loose state. After all this settles, it becomes limestone. Marble, on the other hand, is the hardest kind of calcium carbonate. It is similar to how limestone undergoes great changes under the influence of intense pressure and high temperature.

Calcium carbonate is a chemical compound with the chemical formula CaCO3. It is one of the most abundant minerals on Earth. It is found in the shells of marine organisms such as oysters, clams, and corals. Calcium carbonate is a substance found commonly in three natural forms: chalk, limestone, and marble, formed from ancient marine deposits. Chalk is a soft rock that forms when calcium carbonate sedimentary rocks are not compacted enough and remain in a loose state. After all this settles, it becomes limestone. Marble, on the other hand, is the hardest kind of calcium carbonate. It is similar to how limestone undergoes great changes under the influence of intense pressure and high temperature.

Other synonyms for calcium carbonate include, CaCO3, Calcium Carbonate masterbatch, mineral modifier, PCC, GCC, precipitated calcium carbonate, ground calcium carbonate, pulverized calcium carbonate, calcite, crushed marble, ground limestone, lime, aragonite, chalk etc.

What is Calcium Carbonate used for?

Calcium carbonate is a solid with a crystalline structure. It is a white, odorless powder that is widely used in various industries and in everyday life. Because of its properties, it has a wide range of applications. Calcium Carbonate is a key ingredient used in cement, concrete and mortar to help strengthen and stabilize structures. It is also used as a filler in paints, coatings, plastics and rubber to improve their properties.

It is used in the paper industry as a coating and filler to improve brightness, opacity and printability. Calcium carbonates increase the brightness and improve the appearance of paper as an economical substitute for wood fibers in papermaking.

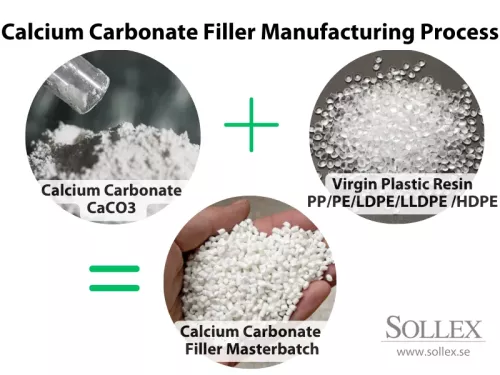

CaCO3 Filler Masterbatch for Plastic Film Production

CaCO3 filler or calcium carbonate filler is a combination of calcium carbonate powder, plastic resin and other specific additives. Plastics companies can freely add pigments to the filler combination to achieve the expected color results without worrying over color blurring. Calcium carbonate has little reaction with other chemicals, making it an inert substance. As a result, CaCO3 can be mixed with most plastic resins without any adverse effect on their properties.

3 Types of Calcium Carbonate: Chalk, Limestone & Marble

We learned more about calcium carbonate as an essential additive for flexible film producers during a discussion with Omya's Magnus Lindsjö at Plastteknik. Chalk, limestone, and marble are the three industrial forms of calcium carbonate. "Chalk is a marine deposit that was formed without pressure. It is dug out of the ground. Limestone is formed under pressure and has to be mined. Marble is probably the most famous calcium carbonate, used for fine Italian statues such as Michelangelo's David. It is created under considerable pressure and is cut into cubes. It is later ground or crushed into powder for industrial use."

Chalk is commonly used as an additive in the manufacture of plastic films; limestone is white and is commonly used in the manufacture of paper. Marble has a finer structure measured in micro- or nanometers. Omya not only extracts calcium carbonate. Additives and coatings are also used to improve the material. This gives the calcium carbonate a different set of properties and purity.

While calcium carbonate is not typically cut like a physical object, it can be ground or milled into a variety of particle sizes, or it can be used as a powder in a variety of applications. The process of grinding calcium carbonate involves breaking larger particles into smaller ones, which increases its surface area and improves its reactivity.

Examples of Calcium Carbonate-Containing Paper and Film Materials

Due to its properties such as opacity, smoothness, and brightness, calcium carbonate is widely used as an additive in paper and plastics. Calcium carbonate is commonly used in magazines and catalogs because it improves the printability and smoothness of the paper. It is also used in paper for printing newspapers. In packaging paper, calcium carbonate is used for stiffness and strength.

Due to its properties such as opacity, smoothness, and brightness, calcium carbonate is widely used as an additive in paper and plastics. Calcium carbonate is commonly used in magazines and catalogs because it improves the printability and smoothness of the paper. It is also used in paper for printing newspapers. In packaging paper, calcium carbonate is used for stiffness and strength.

Calcium Carbonate is also used in the production of synthetic films such as PP and PE. Diapers, gloves, and bags are examples of plastic film products containing calcium carbonate. It can also be found in food packaging and shrink films.

Why Add Calcium Carbonate Modifier to Plastic Films?

Calcium carbonate is added to plastics for two reasons: to reduce the amount of virgin plastic and to improve mechanical properties.

Why is Calcium Carbonate a Good Additive for the Environment when Added to Plastic Film?

Calcium carbonate neutralizes acidic substances. It is used to decrease acidity in water treatment and soil decontamination processes. It is also used in industry to control and reduce emissions of acid gasses such as sulfur dioxide. The manufacturers of plastics can mix the calcium carbonate filler with most of the plastic resins to adapt it to their finished products, since this substance has a great inertness.

Naturally abundant and widely available minerals include chalk, limestone and marble. Calcium carbonate as an additive reduces the amount of petroleum-based polymers. This reduces the overall carbon footprint associated with plastic film production. So from an environmental perspective, reducing the amount of plastic is positive because it reduces the amount of CO2 emissions.

A little math: Calcium carbonate emits 54 kg of CO2 for 1000 kg of calcium carbonate. The production of virgin PE generates 3000 kg CO2 for 1000kg PE. Essentially, using less virgin film reduces your overall CO2 emissions.

How Does Calcium Carbonate Improve the Mechanical Properties of a Plastic Film?

The addition of calcium carbonate as an additive in plastic films serves a number of purposes and provides a number of benefits. As an additive in plastic compounds, calcium carbonate helps reduce surface energy and provides opacity and surface gloss, which improves surface finish.

When calcium carbonate is added, the mechanical properties of the plastic material change significantly. During the extrusion process, the calcium carbonate causes the plastic material to foam and adds more air to the plastic material. In addition, the final product has improved impact strength and modulus of elasticity.

How are chalk, limestone and marble used in industry? Why do you use chalk, limestone or marble as additives in plastic film production?

The use of chalk as an additive in plastic film production is discussed below:

- Filler & extender. Chalk is commonly used as a filler and extender in the production of plastic films. To increase the volume and reduce the overall cost of the film, it is added to the plastic formulation. Chalk particles improve the mechanical properties of the film and reduce the amount of polymer needed by filling the gaps between the polymer molecules.

- Opacity & whiteness. Chalks have excellent opacity and whiteness characteristics that make them a desirable additive in plastic film manufacturing. By adding chalk to the plastic formulation, the resulting film can be made more opaque, preventing light from easily passing through the film. This property is particularly useful in applications where light transmission needs to be minimized. Examples include packaging materials for photosensitive products.

- Enhanced barrier characteristics. Barrier properties can be improved by adding chalk to plastic films. The chalk particles create a tortuous path for gasses and moisture to follow, making it more difficult for them to pass through the film. This helps preserve the freshness and shelf life of packaged products by reducing the ingress of oxygen and moisture.

- Rigidity. Chalk can be used to improve the impact strength and stiffness of plastic films. It improves the film's resistance to tearing and puncturing by strengthening the polymer matrix. This is particularly important in applications where the film is required to withstand the stresses of handling, transportation, and the environment.

- Cost efficiency. Compared to some other additives used in plastic film production, chalk is relatively inexpensive. Its availability in large quantities and low cost make it an attractive choice for manufacturers looking to reduce production costs without compromising film quality and performance.

- Calcium Carbonate also has low oil absorption, good dispersion, low abrasion, and improved corrosion. For the plastics industry, it is therefore an excellent and useful material.

It's worth noting that the amount of chalk added to plastic films can vary depending on specific application requirements. To achieve the desired properties and balance factors such as opacity, mechanical strength, barrier performance, and cost-effectiveness, manufacturers carefully optimize the formulation.

Blades for Slitting Calcium Carbonate-Containing White Plastic Film and Paper

Film slitting is extremely important in film production. When done well, slitting can result in smooth winding and less wrinkling. However, poor slitting has many negative effects.Dust particles can stick to the film and prevent the film from being used in printing or clean room applications. Also, a bad blade may need to be changed more often, which takes time and creates a safety hazard.

Film slitting is extremely important in film production. When done well, slitting can result in smooth winding and less wrinkling. However, poor slitting has many negative effects.Dust particles can stick to the film and prevent the film from being used in printing or clean room applications. Also, a bad blade may need to be changed more often, which takes time and creates a safety hazard.

For the past 20 years, Sollex has been a leading supplier of special blades optimized for slitting and cutting plastic film and paper containing calcium carbonate. For additives such as chalk, limestone and marble we have developed a specific product line with top performance.

Development has been carried out in conjunction with leading film manufacturers. This has verified the performance of Sollex K blades on materials containing Calcium Carbonate in the plastic film production environment. Sollex K blades reduce the amount of dust particles. They also withstand the additional abrasive wear that calcium carbonate creates on the blade during the cutting process.

For PP with additives such as calcium carbonate (this film is very similar to rubber), we recommend Sollex V quality. We also have customers using Sollex K and Z blades that successfully cut PP. If something in between V and K is needed, we have customers who are very happy with Sollex X blades.

We strongly recommend the following products for cutting film containing calcium carbonate:

About Sollex Knives and Blades

Our machine knives and industrial-type razor blades are made of high quality stainless steel with different coatings on the edge or side of the blades. Sole blades we make in solid tungsten carbide or ceramics. If you do not find the blade you are looking for, Sollex are able to manufacture industrial knives and razor blades according to your drawing or needs. You are welcome to contact us at +4635-15 75-00 or at info@sollex.se if you have any questions regarding our industrial razor blades.

Our machine knives and industrial-type razor blades are made of high quality stainless steel with different coatings on the edge or side of the blades. Sole blades we make in solid tungsten carbide or ceramics. If you do not find the blade you are looking for, Sollex are able to manufacture industrial knives and razor blades according to your drawing or needs. You are welcome to contact us at +4635-15 75-00 or at info@sollex.se if you have any questions regarding our industrial razor blades.

About the author Johan Falk is an expert on knives and blades and the CEO of Sollex. You can contact him directly on: 0046 708 744 786 or johan@sollex.se. For general sales questions drop an email to order@sollex.se or call us on 0046 35 15 75 00

Sources

- Interview with Omya’s Magnus Lindsjö at Plastteknik, 2023-05-10

- Wikipedia

- Tidningen Plastteknik

- Polymervärlden

- Online source: www.omya.com

- Online source: polyfill.com.vn/calcium-carbonate-and-how-it-is-used-in-plastic-industry

- Online source: www.plasper.com/en/blow-film/p...

FAQ

Q: Why is calcium carbonate–containing film harder to slit than virgin film?

A: Calcium carbonate is a mineral filler that makes the film more abrasive and less elastic. This increases blade wear, dust formation, and cutting resistance compared to virgin plastic film.

Q: What types of calcium carbonate are used in paper and film production?

A: The three main types are chalk, limestone, and marble. Chalk is commonly used in plastic films, limestone in paper, and marble in high-purity applications with very fine particle sizes.

Q: Why do film manufacturers add calcium carbonate to plastic film?

A: Calcium carbonate reduces the amount of virgin plastic, lowers material cost, improves opacity and stiffness, and enhances mechanical properties such as impact strength.

Q: How does calcium carbonate affect blade lifetime during slitting?

A: The mineral particles significantly increase abrasive wear on the cutting edge, causing faster dulling and higher dust generation if the blade material or coating is not optimized.

Q: What are the main slitting problems when cutting CaCO₃-filled film?

A: Common issues include excessive dust, poor edge quality, frequent blade changes, film wrinkling, and contamination that can affect printing or clean-room applications.

Q: Which blade coatings work best for calcium carbonate–filled films?

A: Ceramic-coated blades (Sollex K quality) are specifically developed to withstand abrasive wear from calcium carbonate while reducing dust formation.

Q: Which blades are recommended for slitting white film with calcium carbonate?

A: Recommended products include 5K, 4-60-030-K, 2-030-K, 2-020-K, 2-013-K, and 642K, all designed for abrasive filler-containing materials.

Q: What blade quality should be used for PP film with high calcium carbonate content?

A: For PP films with high filler levels, Sollex V quality is often recommended due to its extreme durability. K, Z, or X qualities may also work depending on filler concentration and line speed.

Q: How does calcium carbonate influence dust formation during slitting?

A: The mineral particles chip the cutting edge and generate fine powder during cutting. Optimized blade coatings reduce edge breakdown and minimize dust release.

Q: Is calcium carbonate environmentally beneficial when used in plastic film?

A: Yes. Calcium carbonate reduces the amount of petroleum-based plastic and significantly lowers CO₂ emissions compared to producing virgin polymer material.