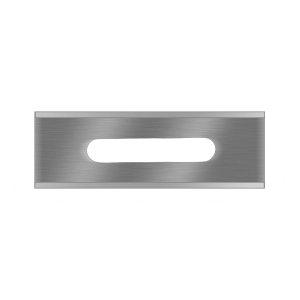

Blades for Lung Meng extrusion blown film machines

Sollex recommends blades for Lung Meng extrusion blown film machines from Taiwan

Blades for extrusion blown film machines made by Lung Meng in Taiwan*

Sollex makes great razor blades for extrusion film machines. We pride ourselves that our razor blades give the plastic film producer performance an endurance for a professional cut and a perfect finished product. Lately we have had the privilege to look into the extensive range of machine manufacturers from Taiwan. The major players in our study were Lung Meng, Diing Kuen plastic machinery company, and Matila industrial co all three serious manufacturers of plastic converting equipment for extrusion, recycling, and printing.

All three have an extensive range of extrusion film machines covering the most common materials such as: HDPE, LDPE, LLDPE, PP, PE, and PA. Sollex have several different blades in different design and in different materials suitable for slitting HDPE, LDPE, LLDPE, PP, PE, and PA in machines from Lung Meng, Diing Kuen, and Matila. For your specific application contact us and we would be happy to support your company to find an optimal cutting solution. This first blog post looks into the details of the Lung Meng product range and blades recommended for those machines.

Blades for HDPE, LDPE, LLDPE, PP, PE, and PA in Lung Meng extrusion machines

Lung Meng also known as Dragon Plastic Machinery is a Taiwanese plastic converting machinery manufacturer founded in 1976. The company prides themselves for their All In Line System, which allows blown film extruders, printers, and bag making machines to work together. Lung Meng carries a wide product range from an inch wide laboratory extruder up to six meter wide, multi-layer, 3x150 mm diameter blown film co-extruder. In addition Lung Meng has zipper profile extruder and variety of water cooling die face cutting recycling equipment. For printing Lung Meng provides a range from simple single color flexographic printing machine up to high speed, high quality, 8 color central impression printing machine.

Our general advice is that no matter how much you invest in production machines it all comes down to the blade slitting the film. If the blade cannot perform on your type of material it does not matter how advance extrusion machine you have. Lung Meng does have a very broad range of machines for most materials. Below is an overview of machine types, machines, materials, thicknesses, and recommended blades.

High speed blown film machine

Lung Meng model: AB-25MI, AH-40MI, AH-40T, EB45T, EB55T, EB65T, AH-45T, AH-55T, AH-65T, AH-75T, AB-90T, AB-100T, AB-120T, and AB-150T

Materials: HDPE, LDPE, LLDPE

Thickness of film: HDPE: 0,008 to 0,07mm / LDPE: 0,012 to 0,2mm

Sollex blade recommendation for high speed blown film machines: Try Sollex Zero Friction blades: type Z, or if you have additives in the film such as white pigments try the type K blades. Contact Sollex and we would be happy to support you with samples so you can test in your production line.

Blown film machine with oscillating haul-off unit

Lung Meng Model: RH-55T, RH-65T, and RH75T

Materials of film: LDPE, HDPE

Thickness of film: HDPE: 0,008 to 0,07 / LDPE: 0,012 to 0,2mm

Sollex general recommendation for blown film: Try Sollex TiN coated razor blades T, or if you have a lot of additives in the film try some of the K blades. Sollex is happy to help you finding a good solution for slitting LDPE and HDPE.

High speed stretch blown film machine with PIB liquid pump systems.

Lung Meng Model: AH-45SC(PIB), AH-55SC(PIB), and AH-75SC(PIB),

Materials of film: LDPE, LLDPE+PIB

Thickness of film: LDPE: 0,012 to 0,25mm

For high speed stretch blown film Sollex recommends Sollex Zero Friction blades: type Z.

High speed twin die blow film machine

Lung Meng Model: AH-45TD, AH-55TD, and AH-65TD

Materials of film: HDPE, LDPE, LLDPE

Thickness of film: HDPE: 0,008 to 0,07mm

Recommendation for High speed twin die blow film machine: Start with Sollex Zero Friction blades: marked with a Z, or if you have additives in the film such as white pigments try the type K blades. If further durability is needed Sollex recommends our C or V products. You are always welcome to contact us for a specific recommendation or samples.

High speed two-color blown film machine

Lung Meng Model: AH-45DH, AH-55DH

Materials of film: HDPE, HMHDPE, LDPE, LLDPE

Thickness of film: HDPE: 0,008 to 0,07mm, LDPE: 0,01 to 0,20mm

Sollex recommends Sollex T or Z types of blades.

High speed pp blown film machine

Lung Meng Model: AP-45, AP-55, AP-65, and AP-75

Materials of film: PP

Thickness of film: PP: 0,02 to 0,08mm

PP is always interesting. For PP with additives such as Calcium carbonate (this film is very rubber like) we recommend Sollex V quality. We also have customers using Sollex K and Z blades who successfully slit PP. If something in between V and K is needed we have some customers who are very satisfied with Sollex X blades.

High speed multi-layer blown film machine

Lung Meng Model: RH-40/40/40TT, RH-45/45/45TT, RH45/65/45TT, RH-55/55/55TT, RH-55/65/55TT, RH-65/65/65TT, RH-65/90/65TT, RH-55/25/42/25/55TT

Materials of film: PE Group, PP, recycled

Thickness of film: LDPE: 0,02 to 0,2mm

General recommendation would be Sollex Z or K blades.

Blades for Lung Meng Printing machines

High speed high quality 6 color C.I. Printing press, High speed stack type flexographic priting press, stack type flexographic printing press.

To our knowledge we have not found any blades in the printing machines we have looked into. However, if you need a blade for your printing service Sollex would be happy to support.

Your input is very valuable

Comments or input on this blog post is very valuable. If you have any experience in using Sollex blades on any specific machine, we are very interested to hear about your feedback. If you would like to test some of our blades contact us and we will see what we can arrange.

Best Regards,

Johan Falk

CEO Sollex AB

T: 00 46 35 -15 75 00

M: johan@sollex.se

—

SOLLEX - Blades for film and for - Cutting edge performance

*The data input this blog post comes from : lungmeng.com.tw, interview with Lung Meng at K19 in Dusseldorf, Sales material provided by Lung Meng. Picture from lungmeng.com.tw. (2020)