Blades for Industrial Plastic Recycling Machines [Customer Case]

Plastic is a very important material and an industry with great potential. Plastics can be recycled, which can save the planet from dangerous levels of CO2 emissions. Unfortunately, most plastic packaging waste is incinerated, resulting in massive CO2 emissions. But there is hope. The circular economy is bringing change and is creating a new level of responsibility for both packaging manufacturers and consumers. In this article, we will talk about industrial plastic recycling machines, knives for recycling machines, and companies that are saving the planet by recycling plastics.

Plastic Recycling Stages

Mechanical recycling of post-consumer plastic packaging waste is a complex chain of activities which generally involves sequential steps that can be summarized in the following phases.

Stage of Plastic Recycling Process | Description |

Collection | Recyclable plastics is collected by businesses and individuals and is sent to processing plants. |

Sorting | At the recycling plant, the plastic is sorted by color and type using sorting / separating machines. A variety of technologies (infrared, color vision sensors, magnet, etc.) can be used for sorting and sampling. With the introduction of NIR based sorting machines, the possibilities of sorting plants have been extended. Automatic sorting lines have roughly the following steps: 1) Opening of waste bags, coarse grinding, and metal removal; 2) Film removal by air or ballistic sorting; 3) A cascade of NIR machines to sort rigid plastics by plastic type; 4) Manual quality control and sorting; 5) Bunker and balers; 6) Storage of baled pressed products |

Washing & Drying | Recyclable plastic must be washed by a plastic washing recycling system before it can be processed. Plastic waste washing lines remove all impurities that may affect the quality of the recycled product. |

Shredding | Plastic shredders (plastic crushers) are used to break down plastic products into smaller pieces. There are several types of industrial shredders: chippers, hammer mills, grinders, shear shredders, and all-purpose shredders. Unlike plastic granulators, shredders are specifically designed to handle larger plastic waste. After shredding, the plastic fragments are sorted by size and weight, where they can be further broken down in the next stage. |

Granulating | A plastic waste granulator (plastic granulation machine) breaks up fragments into smaller fractions. The waste material must also be cleaned. It's a type of dry cleaning process where plastic waste is fed into granulators that grind or shred the plastic for recycling. A centrifuge moment removes contaminants such as fibers from labels through filters. The plastic particles are disinfected and sorted by special machines according to their polymer content. |

Extrusion Pelletizing / Extrusion Granulation | The last step is on the plastic pelletizing extrusion line, where the plastic particles are melted and the resin passes through the extruder die. For example, in an underwater pelletizing machine, polymer filaments emerge from the die plate, solidify as they enter the water, and are then cut into plastic pellets by pelletizing knives. The granulate/regranulate is made on the granulating head. |

Below in the table you can see the main manufacturers of equipment for processing plastic sorted by category of equipment they produce.

Plastic Recycling Equipment | Manufacturer / Company Name |

Plastic Sorting and Separation Equipment Manufacturers (Colour Camera Sorters, NIR Sorters, Other) | Allgaier Process Technology GmbH (Germany), Alrec-Tec GmbH (Germany), Anzai Manufacturing Co., Ltd. (Japan), Austin AI, Inc. (USA), BMCR S.r.l. (Italy), Bühler AG (Switzerland), Cassel Messtechnik GmbH (Germany), Cimbria A.S. (Denmark), Eagle Vizion (Canada), Earth Technica Co., Ltd. (Japan), Ecorema S.L. (Spain), Elkayam Industries (Israel), EntsorgaFin S.p.A. (Italy), GUT GmbH (Germany), Linetechnology GmbH (Austria), Liquisort B.V. (Netherlands), Panizzolo S.r.l. (Italy), Pellenc ST (France), Prodecologia (Ukraine), Sesotec GmbH (Germany), Senro B.V. (Netherlands), SGM Magnetics S.p.A. (Italy), Tomra Systems ASA (Norway) |

Plastic Recycling Washing / Drying Equipment Manufacturer | ASEO Maszyny Sp. z o.o. (Poland), Allgaier Process Technology GmbH (Germany), Application Engineering Company (USA), BCL Equipements (France), B+B Anlagenbau GmbH (Germany), Borate Machinery Inc. (Taiwan), Bollegraaf Recycling Machinery BV (Netherlands), Costarelli S.r.l. (Italy), Comessa S.A. (France), Comet Plastic Equipment LLC (USA), Ecorema S.L. (Spain), Haith Industrial (UK), Sorema, Herbold Meckesheim GmbH (Germany), Hermion B.V. (Netherlands), Hosokawa Polymer Systems (USA), Lindner Washtech (Germany), Plasmaq Ltd. (Portugal), Rotajet Systems Limited (UK), Tecnofer Ecoimpianti Srl (Italy), STF Maschinen- und Anlagenbau GmbH, Costarelli (Italy), Ekolinia Mariusz Mieszkowicz (Poland), Tecnofer Ecoimpianti Srl |

Plastic Granulating Equipment (Granulators) Manufacturers | Adler-Buzzi, AlpineAvian, BOMAC Industries (Netherlands), Bruno Folcieri Srl (Italy), C.M.G. S.p.a (Italy), Camec S.r.l. (Italy), Civemaq s.r.l. (Argentina), Collin, Corima, Cumberland Plastics (USA), DeHart Recycling Equipment (USA), Ecorema S.L. (Spain), Flextrusion Sdn. Bhd. (Malaysia), Forrec Srl (Italy), Gaman Srl (Italy), General Plastics GmbH (Austria), Genius Machinery Co., Ltd. (Taiwan), Hamilton Plastic Systems Ltd. (Canada), Heinrich Dreher GmbH & Co. KG (Germany), Hosokawa Alpine AG (Germany), Iceva AB (Sweden), MG Recycling S.r.l. (Italy), Moretto (Italy), Nielsen Recycling Solutions (Tunisia), Recycling Shredders & Solutions (Netherlands), Sarl Montage Diffusion Technique (France), Tria, Weima Maschinenbau GmbH (Germany) |

Plastic Shredding (Shredders) Equipment Manufacturers | AbyPer SA (Argentina), Adler s.r.l. (Italy), Allegheny Shredders, Inc (USA), ARP GmbH & Co.KG (Germany), Bano Recycling S.r.l. (Italy), Bema A/S (Denmark), Boco Pardubice Machines, s.r.o. (Czech Republic), BP-Recyclingsystems GmbH (Switzerland), C.M.G. S.p.a (Italy), Decoval Servipack SARL (France), Deos Technology s.r.o. (Czech Republic), Donasonic (UK), Ecopolymer (Ukraine), Eldan Recycling A/S (Denmark), Ennex Solutions GmbH (Germany), Esmos Ltd. (Bulgaria), Falubaz Polska S.A. S.K.A. (Poland), Genox Recycling Tech Co., Ltd.(China), Genius Machinery Co., Ltd. (Taiwan), JBF Maschinen GmbH (Germany), Lindner WashTech GmbH (Germany), Lindner-Recyclingtech GmbH (Austria), Machinefabriek de Koning B.V. (Netherlands), MAPA RECYTECH d.o.o. (Croatia), Weima Maschinenbau GmbH (Germany), Meiwa Machine Co., Ltd. (Japan), MOCO, OOO "Mashinostroitelnyj zavod "Vityaz" (Ukraine), Pichano Holding AB (Sweden), Recycling Shredders & Solutions (Netherlands), Rentec n.v. (Belgium), Sabo S.A. (Greece), Vecoplan AG, Wagner Maschinenbau GmbH, Zato S.r.l. |

Plastic Grinding (Grinders) Equipment Manufacturers | Bauermeister, USA, Cogelme S.r.l. (Italy), Flextrusion Sdn. Bhd.(Malaysia), Granutech-Saturn Systems (USA), LIDEM Construcciones Mecánicas S.L (Spain), Mill Powder Tech Solutions (Taiwan), Neue Herbold Maschinen und Anlagenbau GmbH (Germany), Pallmann Maschinenfabrik GmbH & Co. KG (Germany), Piovan S.p.A. (Italy), Process Control Corporation (USA), Rotogran International Inc (Canada), VikoTech Makina San. Ve Tic. Ltd. Sti. (Turkey), Vogelsang GmbH & Co. KG (Germany), Wedlon Automation Co., Ltd. (Taiwan), Wortex Máquinas (Brazil) |

Plastic Extruding (Extruders) Equipment Manufacturers | Alea Plastics Machinery (Poland), Bankov Ltd. (Bulgaria), Binova Srl (Italy), Boco Pardubice Machines, s.r.o. (Czech Republic), CDM Engineering S.r.l. (Italy), Century Extrusion (USA), Comac S.r.l. (Italy), Costarelli S.r.l. (Italy), Esde Maschinentechnik GmbH (Germany), Extricom Extrusion GmbH (Germany), F. lli Maris S.p.A. (Italy), Gneuss Kunststofftechnik GmbH (Germany), ICMA San Giorgio S.p.A (Italy), KraussMaffei Group GmbH (Germany), Reifenhäuser Extrusion Systems GmbH (Germany) |

Plastic Pelletizer / Die-face Cutters Manufacturers | Adler s.r.l.(Italy), Bay Plastics Machinery (USA), CDM Engineering S.r.l. (Italy), Century Extrusion (USA), Coperion GmbH (Germany), Creative Technology & Extruder Co. Ltd. (Japan), Crown Machine uwp, Inc., Davis-Standard, LLC (USA), EREMA Engineering Recycling Maschinen und Anlagen Ges.m.b.H (Austria), ECON GmbH (Austria), Filtec Srl (Italy), Gamma Meccanica Spa (Italy), Genius Machinery Co., Ltd. (Taiwan), Hagihara Industries Co., Ltd. (Japan), Heinrich Dreher GmbH & Co. KG (Germany), Ips Intelligent Pelletizing Solutions GmbH & Co. KG (Germany), Maag Group (Switzerland), Scamex (France), Tecnova Srl (Italy), Trendelkamp Technologie GmbH (Germany) |

Plastic Extrusion - Pelletizing Line Manufacturers | Aquafil Engineering GmbH (Germany), Aranow Altero Recycling Machinery S.L. (Spain), Bausano & Figli Spa (Italy), Century Extrusion (USA), Clextral SAS, Costruzioni Meccaniche Luigi Bandera SpA (Italy), Crown Machine uwp, Inc., Davis-Standard, LLC, EREMA Engineering Recycling Maschinen und Anlagen Ges.m.b.H (Austria), ECON GmbH (Austria), Gamma Meccanica Spa (Italy), General Plastics GmbH, KraussMaffei Group GmbH, Kween B Limited, Makiane International Corporation, Next Generation Recyclingmaschinen GmbH (Germany), Processing Technologies International, LLC (USA), Promeco SpA (Italy), ProTec Polymer Processing GmbH (Germany), Scamex (France), Starlinger & Co Gesellschaft m.b.H. (Austria), Tecnova Srl (Italy), Union Officine Meccaniche S.p.A. (Italy) |

Rondo Plast AB (Sweden) Recycling Technologies for Circular Economy

The demands of Tier One customers have changed. Instead of asking for 100% virgin plastic material, buyers are now specifying how much recycled material a product should contain - for example, 25% of post-consumer recycled plastic (Read more about PCR-plastic in our article). This has had a massive impact on the amount of plastic that is being recycled rather than being incinerated.

The demands of Tier One customers have changed. Instead of asking for 100% virgin plastic material, buyers are now specifying how much recycled material a product should contain - for example, 25% of post-consumer recycled plastic (Read more about PCR-plastic in our article). This has had a massive impact on the amount of plastic that is being recycled rather than being incinerated.

The mantra of reduce, reuse, and recycle is very true for Sollex customer Rondo Plast AB. Rondo Plast offers quality-assured recycled plastic raw material with a fully or partially recycled raw material base for injection molding and extrusion. On a typical Tuesday, Rondo Plast recycles as much as 9000 kg of plastic. The plastic comes from all over Europe. It is sorted, cleaned, and washed at the Rondo Plast plant in Ystad, Sweden.

Rondo Plast is able to recycle shredded plastic, labels, and nonwovens. But it has to be sorted. The main issue for Rondo Plast is capacity. They are in a constant process of moving existing plastic reprocessing lines to make room for new recycling machinery.

Post-Consumer Recyclates, Recycling, and Recycled Pellets

In theory, fully recyclable mono-material packaging can be 100% recycled if you have a plastic film washing and pelletizing line to process post-industrial waste. Basically you can take any sorted, clean plastic material and granulate it with a plastic granulator.

Regranulates and plastic pellets based on PE, HDPE, LDPE, PP, PS are used for the production of new plastic products. By using PE, PP regranulate, plastic products are made from 100% recycled polyethylene and polypropylene. This also means it is possible to produce high-quality recycled plastic products in a sustainable way without compromising quality standards.

Regranulates and plastic pellets based on PE, HDPE, LDPE, PP, PS are used for the production of new plastic products. By using PE, PP regranulate, plastic products are made from 100% recycled polyethylene and polypropylene. This also means it is possible to produce high-quality recycled plastic products in a sustainable way without compromising quality standards.

If you have that in volume you can save the planet by sending it to companies like Rondo Plast. They have PP and PE film pelletizing machines that can transform waste to valuable PP and PE pellets.

How is Plastic Waste Sorted at Rondo Plast?

Sorting plastic waste is difficult, time-consuming, and costly. The key to getting high-quality plastic pellets and regranulate is to have sorted, clean plastic. A plastic waste separation machine and a plastic film washing machine are used to sort and then clean the plastic film.

In a laboratory, Rondo Plast can make a small plastic plate. Tensile and impact tests give you an indication of the type of plastic waste you are dealing with. Rondo Plast can often identify the type of plastic mixture and its recycling potential based on the smell of burnt plastic.

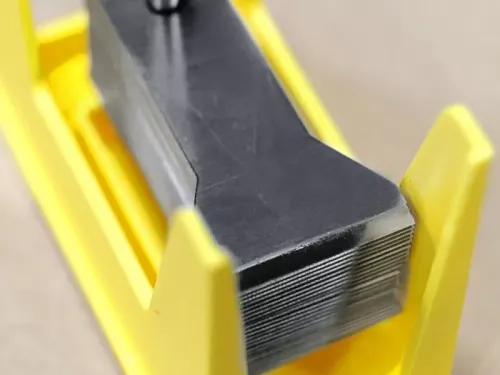

Sollex Granulator and Pelletizer Knives for Plastic Recycling Machines

Recycling any plastic requires knives and blades at certain stages of processing. "Knives are in all of our recycling machines," says Victor Bladh, production manager at Rondo Plast. When making knives for plastic recycling, durability and performance are important. They must don't interfere with the flow of recycling materials. Fortunately for Rondo Plast, "Sollex blades save money every year because of their price, durability, and performance," says Victor.

Recycling any plastic requires knives and blades at certain stages of processing. "Knives are in all of our recycling machines," says Victor Bladh, production manager at Rondo Plast. When making knives for plastic recycling, durability and performance are important. They must don't interfere with the flow of recycling materials. Fortunately for Rondo Plast, "Sollex blades save money every year because of their price, durability, and performance," says Victor.

After sorting and cleaning, it is time for the recycling process that companies like Rondo Plast carry out. Suppliers of recycling machines, such as Erema, Weim and Wipa show proven and tested technology. Rigid plastics are usually easier to recycle than flexible materials.

As mentioned above, at the extrusion stage, the recyclate is heated and pressed through a die. At the end of the extrusion process, the melted plastic stream is cut into pellets. Therefore, the recycling of plastic waste requires the use of granulator knives and pelletizer knives.

It is imperative that the knives used are optimized for your granulator and pelletizer machines. Sollex has several knives and blades for Erema recycling machinery in stock. We also design, develop, and manufacture knives for customer drawings. Contact us and we will be happy to assist you with your granulator or pelletizer process.

Recycling Suggestions for Saving Our Planet

Viktor at Rondo Plast suggests that we should make companies responsible for their waste. Instead of sending mixed cardboard and plastic to be burned and creating CO2, use local firms that can recycle and reuse your plastic waste.

General production guidelines to recycle plastics, reduce CO2 and save the planet

General production guidelines to recycle plastics, reduce CO2 and save the planet

- Use mono-materials so that the finished product can be recycled directly.

- Avoid dark-colored plastics, as they are difficult or sometimes impossible to recycle and increase the cost of recyclables.

- Avoid printing on packaging, as it makes sorting difficult and reduces the value of recyclables.

- To save energy, chemicals, and filters in the recycling process, use labels made of the same material as the packaging. Then it doesn't need to be removed, separated or cleaned.

- For proper consumer recycling, make sure all products are labeled with the correct DIN code.

Here are some general tips for consumers on how to recycle plastic, save CO2 and protect the planet

- Avoid purchasing dark-colored or printed plastics. Buy clear or light-colored.

- For recycling, clean plastic packaging.

- Remove labels that are made of a different material than the packaging.

- Please sort the clear plastic into specific materials as indicated by the DIN label.

About Sollex Knives and Blades

Our machine knives and industrial-type razor blades are made of high-quality stainless steel with different coatings on the edge or side of the blades. Sole blades we make in solid tungsten carbide or ceramics. If you do not find the blade you are looking for, Sollex is able to manufacture industrial knives and razor blades according to your drawing or needs. You are welcome to contact us at +4635-15 75-00 or at info@sollex.se if you have any questions regarding our industrial razor blades.

The author Johan Falk is an expert on knives and blades and the CEO of Sollex. You can contact him directly on: 0046 708 744 786 or johan@sollex.se. For general sales questions drop an email to order@sollex.se or call us on 0046 35 15 75 00

Sources:

- Återvinningsbara plastförpackningar - En guide för ökad återvinning av plastförpackningar https://www.ri.se/sites/default/files/2020-05/Guide_%C3%85tervinningsbara%20plastf%C3%B6rpackningar_v1-2019.pdf, Accessed the 21th February 2023

- Rondo Plast AB Hemsida - www.rondoplast.se

FAQ

Q: What are industrial plastic recycling machines?

A: Industrial plastic recycling machines are used to sort, wash, shred, granulate, extrude, and pelletize plastic waste so it can be reused as recycled raw material.

Q: What are the main stages of mechanical plastic recycling?

A: The main stages are collection, sorting, washing and drying, shredding, granulating, extrusion, and pelletizing.

Q: Why is sorting important in plastic recycling?

A: Sorting ensures that plastics are separated by type and quality, which is necessary to produce clean, high-quality recycled pellets.

Q: What types of knives are used in plastic recycling machines?

A: Plastic recycling machines use shredder knives, granulator knives, and pelletizer knives depending on the processing stage.

Q: Why are pelletizer knives important in plastic recycling?

A: Pelletizer knives cut molten plastic into uniform pellets and directly affect pellet size, quality, and production stability.

Q: Which plastics are commonly recycled into pellets?

A: Common recyclable plastics include PE, HDPE, LDPE, PP, and PS.

Q: What makes flexible plastic film difficult to recycle?

A: Flexible plastic film is difficult to recycle due to contamination, mixed materials, labels, inks, and adhesives.

Q: Why is blade durability critical in recycling machinery?

A: Durable blades reduce downtime, maintain consistent cutting performance, and lower overall operating costs.

Q: Can Sollex supply knives for specific recycling machines?

A: Yes, Sollex supplies standard knives for recycling machinery and manufactures custom knives based on customer drawings.

Q: How does plastic recycling help reduce CO₂ emissions?

A: Recycling plastic reduces incineration and the need for virgin raw materials, which significantly lowers CO₂ emissions.