Blades to Cut Latex, Silicone, TPE, ETFE, PTFE [Customer Case]

In this article we will look at a case study of a manufacturer who had a problem with cutting latex tubes for medical application and asked Sollex for a blade that would give a clean cut.

In this article we will look at a case study of a manufacturer who had a problem with cutting latex tubes for medical application and asked Sollex for a blade that would give a clean cut.

Latex Elastic Material in Medical and Healthcare

Latex material is known for its exceptional elasticity, which allows it to be stretched and then return to its original shape without permanent deformation. In the medical field, latex is used in various applications such as surgical tubings, elastic bandages, surgical drains, and in some types of catheters. It also has good resistance to acids, alkalis, and other chemicals.

There are several other soft elastic materials that have properties similar to latex and can be used to make medical tubing: silicone tubing, thermoplastic tubing, ETFE tubing, PTFE tubing, polyamide, polycarbonate, polyethylene, polyimide, polyolefin, polypropylene, polyvinyl chloride, thermoplastic elastomer tubing, nylon tubing, non-latex tubing.

Some examples of using latex in the medical and healthcare: Medical gloves, Catheters, Elastic bandages, Tourniquets, Surgical tubing, Respiratory bags.

Latex tubing, made from natural rubber latex, is a highly stretchable and elastic material widely used in various medical and non-medical applications.

Cut Latex and Other Elastic Materials like TPE, EFTE, PTFE, Silicone, Nylon

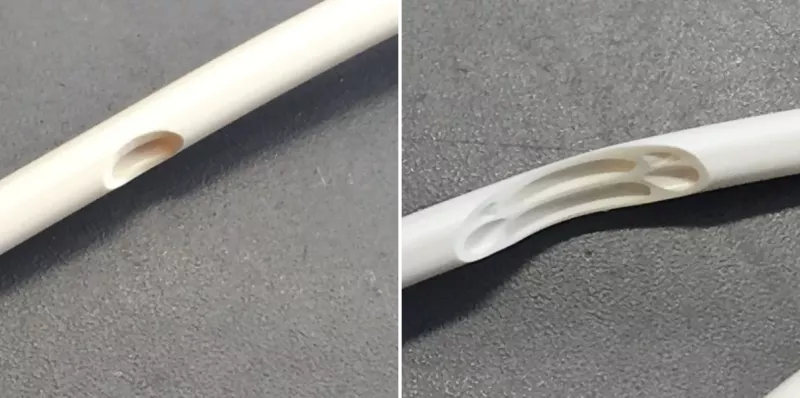

Cutting latex, particularly in the form of thin sheets or tubing, can be challenging. Latex is highly elastic and tends to stretch rather than cut cleanly. When you apply a cutting force, the elastic material stretches away from the blade or cutting tool instead of being sliced through. The material bends and twists, which makes exiting the material trickier and a clean cut almost impossible.

Latex Tubing Cutting Test [Customer Case]

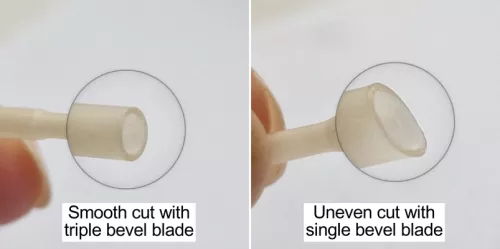

On behalf of our client, we conducted experiments to cut thin latex surgical tubes and to find the best blade for cutting elastic tubing with a clean cut. And these are the conclusions we reached as a result of the experiment and the challenges we faced.

4 Challenges When Cutting Stretchy Materials such as Latex

- Normal blades are either too thick and blunt or too thin and flexible. The thick, blunt blade presses through leaving a not-so-clean cut and a material tail. Too-thin blades slides on the stretchy material.

- The sharpness and type of cutting tool play a significant role. Dull blades will struggle to cut through latex cleanly and are more likely to pull or tear the material. A very sharp, thin blade is typically required for a clean cut.

- The thickness of the latex and its uniformity can also impact how easily it can be cut. Thinner latex may be more prone to tearing or stretching, while thicker latex requires more force to cut through, which can be difficult to control precisely.

- The technique used to cut latex is also important. It often requires a steady, controlled motion with consistent pressure. Any variation in the cutting motion can lead to jagged edges or tearing.

3 Cutting Techniques for Cutting Thin Latex or Elastic Polymer Materials

When cutting thin latex or very resilient soft polymer materials, there are 3 things we have found to work well.

- Use reinforced single edge razor blade, double sided, triple bevel blades, 62G

- Use single sided double bevel blades

- Cutting material through a column with a thin razor blade

First thing first, fixing the material is imperative for any type of soft material cutting. Leading the material in a drilled hole or die is strongly recommended.

Three other things are extra important when cutting elastic materials like latex. The blade needs to be kept straight. It needs to be pretty thin. Finally and most important, the edge needs to be extra sharp. Keeping the blade straight can be done by reinforcing its back-side or letting the slitting blade cut through a column that keeps the blade straight at all times.

Industrial Blades to Cut Elastic Materials

As a result of the tests, Sollex was able to find a blade that met the specified requirements. The customer from the medical industry, a manufacturer of latex tubing and products, also adapted the recommendations on cutting techniques and easily put them into practice. The company was very satisfied with the result and the clean cut they now get on their latex products.

If you are also looking for an industrial blade for cutting latex or other elastic materials for the production of catheters, tubes, and other medical products, contact Sollex, we will help you.

Sollex is a Swedish supplier of industrial slitter blades and material converting knives! We offer cutting products that utilize cutting-edge technology and performance to enhance manufacturing and converting processes while addressing various challenges. With the right knives and blades, you can get simplified maintenance, time savings, and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se Telephone: +4635–15 75 00 Address: Box 5161, 200 71, Malmö, Sweden

FAQ

Q: Why is cutting elastic materials like latex challenging?

A: Latex and similar materials are highly elastic and tend to stretch, bend, or twist away from the cutting tool instead of slicing cleanly. When a cutting force is applied, the material stretches, which makes achieving a clean cut almost impossible.

Q: What are the main challenges faced when cutting stretchy materials?

A: The four main challenges are: 1) Standard blades are either too thick (leaving tails) or too thin (sliding on the material). 2) Dull blades pull or tear the material. 3) Thinner elastic material is more prone to tearing. 4) The process requires a steady, controlled motion with consistent pressure, as variations lead to jagged edges.

Q: What are the three cutting techniques recommended for thin elastic polymer materials?

A: Sollex found these three techniques work well: 1) Using reinforced single-edge razor blades (like double-sided, triple-bevel blades, 62G). 2) Using single-sided double-bevel blades. 3) Cutting the material through a column (drilled hole or die) with a thin razor blade to keep the blade straight.

Q: What are the three most important blade properties for cutting elastic materials?

A: The three vital factors are: the blade must be kept straight (often by reinforcement), it needs to be relatively thin, and the cutting edge needs to be extra sharp.

Q: In what medical applications are latex and similar elastic materials used?

A: Elastic materials like latex, silicone, TPE, and PTFE are widely used in medical and healthcare products such as surgical tubing, elastic bandages, surgical drains, catheters, and medical gloves.

Q: How did Sollex solve the customer's problem with cutting latex tubing?

A: Sollex conducted extensive tests and found a specific industrial blade that met the clean-cut requirement. The customer then adopted the recommended cutting techniques (like fixing the material in a drilled hole) into their production process.