Tungsten carbide tools with extreme tolerances for a MedTech

Sollex supplied carbide tools to customer drawings with extreme tolerances for a very demanding international client in the medical technology sector. The dimensions of the tool have been measured in exact hundredths with tolerances down to five thousandths (+ 0 / -0.005 to be exact). Similarly, the surface roughness Ra 0.01 has touched the extreme. In the project, Sollex has delivered unique measurement protocols where we measured the tool's tolerances and surface smoothness.

In January, Sollex delivered another 10 new shipments of extreme tolerance carbide tools for injection molding plastics. This shipment demonstrates Sollex's high repeatability in producing complex cemented carbide tools with extreme dimensions and tolerances.

Because cemented carbide is extremely hard and wear resistant, cemented carbide molds can be used to produce high-precision components with long life and high accuracy. Carbide is also resistant to high temperatures and corrosion, making it suitable for use in abrasive environments. Injection molding tools are expensive to produce, but their long life and high performance make them a cost-effective option in the long run. Injection molding is a manufacturing process that can produce thousands or millions of identical plastic parts, it is critical that the molding tools are durable enough to withstand the wear and deformation that occur during the injection molding process.

Sollex can also offer the nearly impossible - making radial transitions with cemented carbide tools. The radial transitions that Sollex can provide are between two thicknesses of 0.4 mm and 0.1 mm in cemented carbide tools. Radial transitions provide a reduction in capillary force in the production material where the cemented carbide tool is used, compared to linear transitions.

In the carbide tool project, Sollex has truly excelled in developing unique carbide tools for customers with extreme dimensions, tolerances, and surface smoothness in tool design. We are proud and pleased with our beautiful knives and can now say that we can also manufacture cemented carbide tools.

Learn more about metal carbide in a series of our articles:

- Tungsten Carbide - Properties and Applications of Tungsten Carbide: Part 1

- Tungsten Carbide and Technology: Part 2

- What Kind of Solid Tungsten Carbide Does Sollex Use: Part 3

Order Solid Tungsten Carbide Machine Knives, Knife Blades and Plotter Knives

Sollex has a range of tungsten carbide knives, which you can find on our website by searching for "tungsten carbide". Sollex will fulfill your order in a reasonable time, with the best workmanship, high-quality material and at a reasonable price if you need custom-made solid tungsten carbide knives that are not in the range or that have a special design, characteristics, surface polishing, and even surface coating.

Sollex has a range of tungsten carbide knives, which you can find on our website by searching for "tungsten carbide". Sollex will fulfill your order in a reasonable time, with the best workmanship, high-quality material and at a reasonable price if you need custom-made solid tungsten carbide knives that are not in the range or that have a special design, characteristics, surface polishing, and even surface coating.

To order tungsten carbide knives send us an email to order@sollex.se with your order details and we will send you a quote within an hour

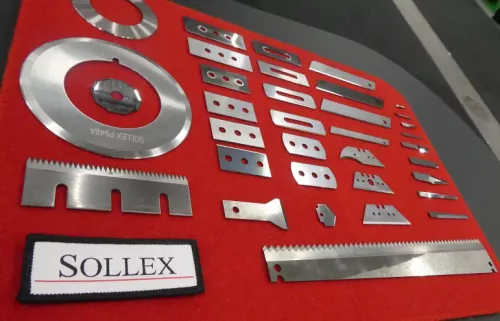

Sollex is a Swedish supplier of industrial slitter blades and converting machine knives! We have cutting products with cutting-edge technology and performance that improve manufacturing and converting processes and solve problems. With the right knives and blades you can get simplified maintenance, time savings and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Address: Box 5161, 200 71, Malmö, Sweden

FAQ

Q: What kind of tools did Sollex supply with extreme tolerances in this project?

A: Sollex supplied solid tungsten carbide tools for a demanding international client in the medical technology sector, primarily for injection molding plastics.

Q: What were the specific extreme tolerances achieved on these carbide tools?

A: The tool dimensions were measured in exact hundredths, with tolerances down to five thousandths of a millimeter (+0 / -0.005) and a surface roughness of Ra 0.01.

Q: Why is cemented carbide preferred for injection molding tools?

A: Cemented carbide is extremely hard and wear-resistant, allowing the tools to produce high-precision components with long life and accuracy. It is also resistant to high temperatures and corrosion.

Q: Can Sollex create complex radial transitions with cemented carbide?

A: Yes. Sollex successfully delivered complex radial transitions between two thicknesses of 0.4 mm and 0.1 mm in cemented carbide tools, which helps reduce capillary force in the production material.

Q: How does Sollex ensure the high precision and quality of these tools?

A: Sollex ensures precision by delivering unique measurement protocols where the tool's tolerances and surface smoothness are verified, demonstrating high repeatability in production.