Shear Slitting: Precision Cutting Guide

What is shear slitting in industrial converting? Shear slitting is a cutting method that uses paired circular knives to create a clean “scissor effect” on rolled materials such as plastic film, paper, foil, tape, laminates, and nonwoven. It is the most versatile slitting technique for slitter rewinders, delivering smooth, dust-free edges at high speeds. Compared to razor or score slitting, shear cutting provides superior edge quality and is widely used in packaging, printing, and industrial converting. In this article, we will take a closer look at shear slitting. You can learn more about razor and score slitting here.

Content:

- What is a slitter machine

- What is shear slitting process

- Difference between cutting and slitting

- How shear slitting works

- Materials to be processed when shear slitting

- Tangential vs wrap shear slitting

- Advantages and disadvantages when shear cutting

- Shear slitting knife types

- Choosing the right knife profile

- Lubrication

- Order shear slitter blades

Shear Slitting in Industrial Converting

What is a slitter machine and how does it work?

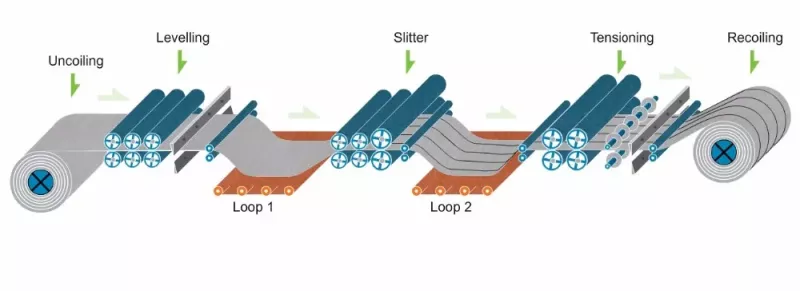

Slitter rewinders are widely used in various industries to process materials such as paper, film, foil, packaging, textiles, nonwovens and more. A slitter rewinder is an industrial cutting machine used for slitting roll materials into smaller rolls and winding them onto spools. The machine features circular or razor blades that cut the material into set widths as it passes through.

Slitter machines are designed for cutting different materials, so therefore there are the following slitting techniques: razor slitting using thin industrial razor blades, shear slitting using rotary shear cut knives ( for example, paired top and bottom rotary knives) and crush or score slitting. Because shear slitting performs well at high speeds, it is the preferred slittingchoice for converters working with slitter rewinder machinery.

What is the difference between cutting and slitting?

What is the difference between cutting and slitting?

Slitting will always mean cutting the material web lengthwise, and cutting will mean cutting both lengthwise and crosswise. Hence the name of the roll slitting machine is a slitter.

How Shear Slitting Works

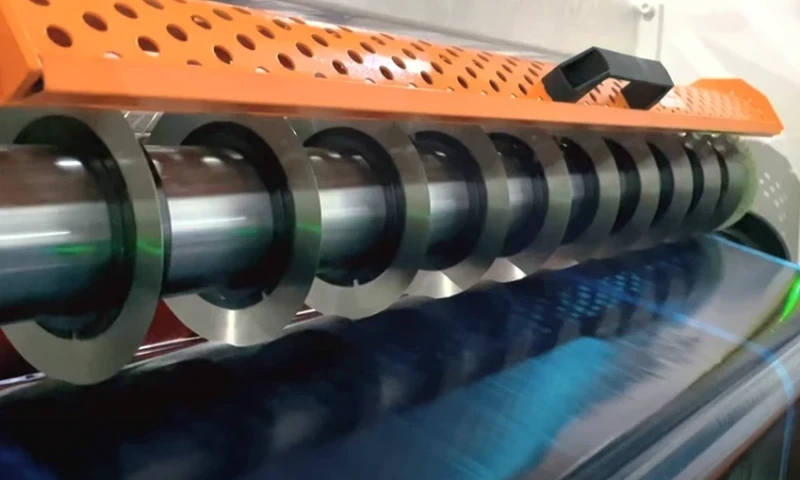

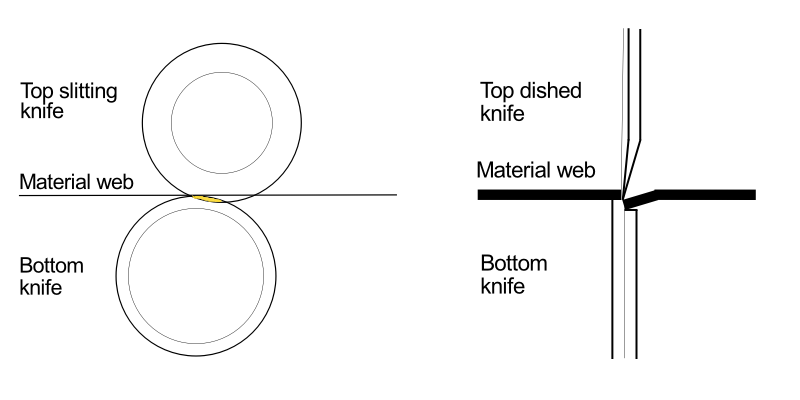

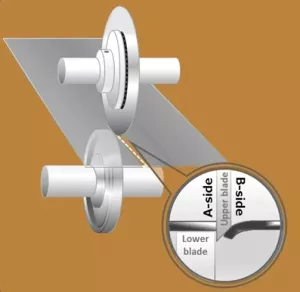

Shear slitting uses a pair of rotary knives: a top knife usually dish-formed, referred to as the male knife, and a bottom knife, referred to as the female knife, together create a rotating "scissor" effect on the incoming web.

The slitter machinery, when shear slitting, has circular slitter blades that are positioned across the width of the web material and cut it into smaller widths as it passes through. Top circular slitter blades mounted in an adjustable holder. The female knives are mounted on a rotating shaft. As the web moves between them, the material is cleanly separated by the shearing action of the overlapping blades. Afterward, the newly cut strips pass through rollers that rewind them onto smaller spools.

Imagine holding a pair of scissors and cutting through a sheet of paper. The same principle applies to shear slitting, where the angle of the junction between the knives is the linchpin for a perfect slit.

For shear slitting, the best cutting angle is determined by the diameter of the top and bottom knives, the material thickness, and the position of the top and bottom knives.

Typically, the bottom knives function as drivers, while the top knives are not driven but spin due to the friction between the bottom knife and the material. To achieve a shear cut, the bottom knives must operate 3-5% faster than the top knives.

“In BOPP film slitting, properly set shear knives can run 1000–1500 km before resharpening.”

Which materials can be processed with shear slitting?

Shear slitting is suitable for a wide variety of substrates. It is especially effective for coated and uncoated paper, including grades used for printing, labeling, and packaging. It also works well on thicker plastic films such as polyester, polyethylene, and polypropylene. Multi-layer laminates, labelstock, and even some technical textiles can be efficiently processed using shear blades. Commonly, the slitter machine cuts the following materials:

- Paper. Various types of paper, including fine writing paper, coated paper, cardboard, and corrugated fiberboard, can be slit using shear slitting.

- Plastic films and foils. This method often involves slitting thin plastic films made from materials like polyethylene, polypropylene, PVC, and polyester.

- Metal foil. Metal foils, such as aluminum foil, can be precisely cut with shear slitting.

- Nonwoven material. These fabrics, which are not woven, are used in medical, hygiene, and industrial applications.

- Adhesive tape. Adhesive tapes with various backing materials can be slit to the required widths.

- Textiles. Certain types of textiles that require a clean-cut edge can also benefit from shear slitting.

- Rubber. Rubber or rubberized materials can be processed using shear slitting.

- Laminates. Composite materials are made by bonding layers of different substances, which could include a combination of films, papers, and foils.

The choice of shear slitting as the preferred method typically depends on the properties of the material, such as its thickness, tensile strength, and whether it is laminated or coated, as well as the required quality of the finished edges. Unlike razor slitting, which slit the web with a stationary blade, shear slitting displaces and compresses the material slightly before cutting. This results in a smooth, controlled edge without fraying or dust. To achieve consistent results, the knife overlap, cutting angle, and pressure must be precisely adjusted. Many modern machines are equipped with automatic knife positioning systems that allow operators to set up slits quickly and accurately using a digital interface.

What are the 2 shear slitting techniques: tangential vs wrap?

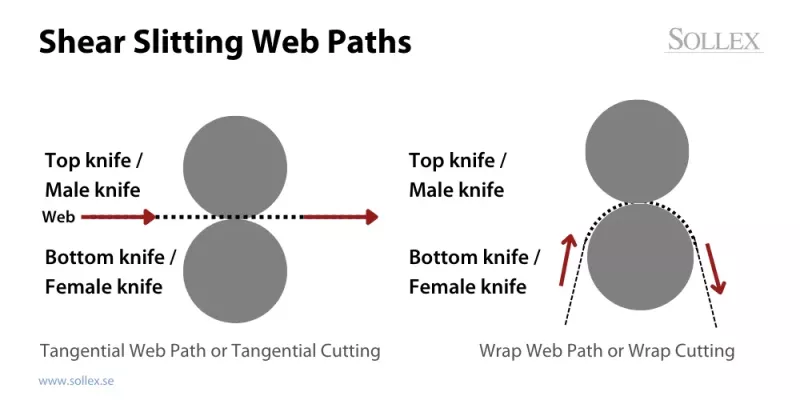

There are two types of shear cutting: wrap slitting and tangential slitting.

Tangential slitting involves cutting the material on a horizontally moving web by means of a knife that touches the material web tangentially. In tangential slitting, the cutting point is in a small intersection area where the web kisses the top of the bottom band. The problem with this method is that the depth of cut is very shallow and must be adapted correctly to the material on the cutting machine. In general cases for tangential cutting, it is recommended to have the depth of intersection of the upper slitter knife with the lower one when cutting plastic film and foil to a depth of 0.50mm-0.75mm, flexible packaging and fabrics to 0.60 mm-0.90 mm, and non-woven materials to 0.75 mm-1 mm.

Wrap slitting involves cutting where the top slitter knife is positioned over the web and the web itself is wrapped around the bottom belt or axel of the slitter. In this case, the cutting point can be anywhere along the wrapped web. This provides greater stability and control at the moment of cutting, which is especially important at very high speeds or when managing narrow edge trims. Vacuum-assisted trim removal is usually placed directly at the slit line to capture edge waste immediately and prevent breakage or flutter.

What challenges occur when setting depth in shear slitting?

When slitting with the shear cutting method, the decisive factor influencing the cut quality and edge condition of the material is, in addition to quality and correctly selected knives, material speed, pressure, cutting angle, and also the correct setting of the intersection depth of the top and bottom knives. You will get poor cut quality and bulging edges if you set the intersection depth too high.

If you program the depth too shallow, you will get interrupted edges and poor quality of the cutting process with many waste products. If you use circular top knives that are too small in diameter or knives with a worn cutting edge, it will reduce the area of intersection between the top and bottom knife and the material and will result in a compromised, uncontrolled cutting process.

What are the advantages and disadvantages of shear slitting?

One of the most compelling aspects of shear slitting is its adaptability. It handles a diverse array of materials with ease, making clean and precise cuts that are essential for the end-use of the products. From the heavy-duty demands of thick polyester to the delicate touch required for thin foils, shear slitting adjusts its embrace to accommodate the unique properties of each material.

One of the most compelling aspects of shear slitting is its adaptability. It handles a diverse array of materials with ease, making clean and precise cuts that are essential for the end-use of the products. From the heavy-duty demands of thick polyester to the delicate touch required for thin foils, shear slitting adjusts its embrace to accommodate the unique properties of each material.

A critical factor in the quality of the cut is the knife speed relative to the web speed. The angle at which the blades meet controls the outcome, regardless of the knives' speed. This flexibility is what allows shear slitting to cater to a broad spectrum of materials and thicknesses, delivering a cut that is clean and without burrs or tears.

The setup of shear slitting machinery speaks to its commitment to precision. Aligning the top and bottom knives, calibrating the pressure, and ensuring the optimal overlap of the blades is a meticulous process. However, this attention to detail pays off in the consistency of the cut, with minimal dust and a sharp edge that is both aesthetically pleasing and functional.

The technique incorporates driven rolls to keep constant tension in the slitting area, ensuring the slit width remains consistent. This is particularly important for high-speed operations and for materials where any variation could compromise the quality of the final product.

Shear Slitting Knives & Blades: Geometry and Features

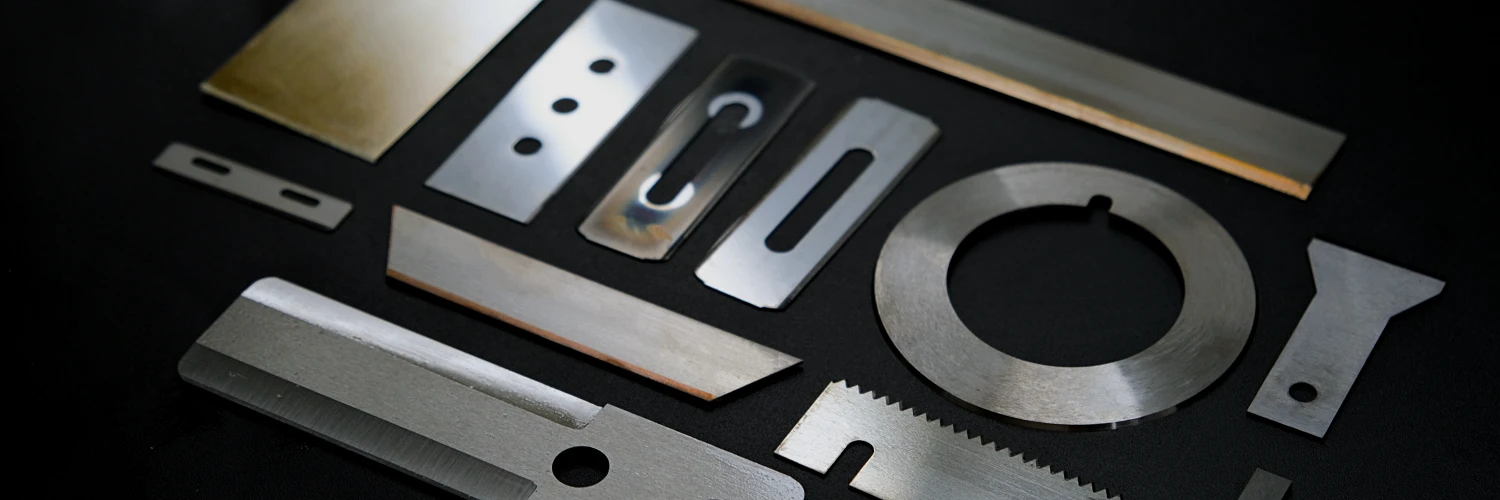

Shear slitting blades can be referred to as top / bottom slitter knives, circular slitter blades, circular shear slitters, rotary slitter knives, or rotary shear blades. The top (male) knives can be of two types - flat and dished and the bottom (female) knives - anvils or plain bore bottom knives, grooved and multi-grooved. “Converters cutting PET film typically use dished top knives in HSS-M2 for precision edge quality.”

Here are the types of shear-cut knives typically used in shear-cutting processes.

| Type of Shear Knife | Description | Slitting Material |

|---|---|---|

Circular Knives | These are the most common type of knives used in shear slitting. They can be made of various materials, including D2, HSS-M2, and Tungsten Carbide. | The material chosen often depends on the type of material being slit, the desired longevity of the blade, and the quality of the cut edge. |

| Dished Top Knives | These machine blades, also called male slitting knives, have a slight concave shape like a dish, which helps to maintain the "wrap angle" on the knife edge during slitting paired with a bottom knife. Material for the knives: D2, HSS-M2, Tungsten Carbide. Example:RDD130x100,RDS65x40 | Top dished circular knives are commonly used for slitting and converting paper, plastic film and foil, rubber, textiles. |

| Flat Top Circular Knives | These are the rotary knives that are mounted on the top slitting shaft. They are often manufactured with a beveled edge and can be fine-tuned in terms of angle and sharpness to match the specific slitting task. Top knives come in various diameters and thicknesses to accommodate different slitting scenarios. Example: P918,R71-SHARP,R105 | Flat top circular knives are commonly used for slitting and converting paper, cardboard, carton, non-woven, metal foil. |

| Bottom Knives | Also known as anvils or female knives, these are matched with the top knives and are mounted on the bottom shaft. They usually have a hardened, smooth surface against which the top knives cut. The main principle for a bottom knife is to position the material web and stretch it for the top knife to cut it. Example: P804B,RBF130 | |

| Multi-Groove Bottom Knives | These are bottom knives that feature multiple grooves. They allow for quick adjustment of slit widths by moving the top knives into different grooves without the need to replace the bottom knife. |

How do you choose the right knife profile for shear slitting?

Choosing the right knife style is important for effective shear slitting. For example, double hollow ground blades are preferred when processing soft foils to avoid rolling or tearing at the edge. Standard flat-profile blades work well for general-purpose paper slitting. When working with thick films or thermoformed products, wide-rim knives are typically used. These allow the displaced material to flow around the cutting edge, avoiding raised edges and burrs that may affect downstream processing.

For materials with brittle coatings, even the clean shear of the blade may cause edge fragmentation. In such cases, immediate post-slitting vacuum extraction is used to remove fines and debris from the cut area. Each material behaves differently under shear force, so blade selection and setup must be adjusted accordingly.

Why are lubrication and web cleaning important in shear slitting?

When processing adhesive-coated webs, such as labelstock or foam tapes, there is a risk that glue will build up on the blades. This can cause uneven cuts, increase friction, and shorten blade life. To avoid this, many systems include blade lubrication mechanisms.

“For adhesive tapes, lubrication prevents glue buildup that otherwise reduces blade life by 50%.”

Lubrication may be delivered through felt wicks, roller systems, or microinjection nozzles. Some systems use re-saturation controls based on web length or run time. This ensures that adhesive build-up is minimized and that the cut remains clean and consistent.

How does automation improve shear slitting productivity?

Modern shear slitting machines often include automation that goes beyond knife positioning. Core placement systems, guided by lasers or digital markers, align rewind cores precisely with the knife positions. Operators simply enter the slit widths and web width into the control system, and the machine adjusts the blade positions and indicates where to place each core.

Where can I order shear slitting knives and blades?

We supply shear slitter blades according to your needs and designs.

Possible characteristics that influence the choice of a circular industrial knife:

- shape and diameter of the hole in the knife for fixation in knife holders

- the cutting material and its characteristics

- cutting speed

- the outside and inside diameters of the circular knife

| Diameter of circular knives | Sollex Knife Product Item |

| Circular knives up to 60 mm in diameter | R30, R28X6X4-70, R30-010, R30-010-X, R45X8, RB60-1, R18-2, R28-5, R45 |

| Circular knives over 60 mm in diameter | R71-SHARP, R71-BLUNT, R150, P829-1,R70x40x1, P847, P855-1, P829-3, P829-2, P834, P831, RDS75x40x1, RDD130X80, RDD130X100, RDD140X70, RDS65X40, P881A |

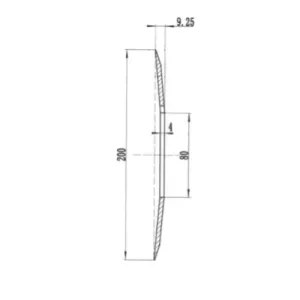

Dished circular knives dimensions

| Outer diameter | 62–250 mm |

| Inner diameter | 40–140 mm |

| Thickness | 0,6–4,0 mm |

| Standard cutting angle | 30° |

| Standard inner dished angle | 5° < |

| Materials | D2, HSS-M2, Tungsten Carbide |

| Polishing | Standard Ra 1.6 or Mirror-polishing on demand |

| Coating of knife edge < | On demand |

Flat top circular knives dimensions

Outer diameter | 18–900 mm |

Inner diameter | 20–140 mm |

Thickness | 0,3–10,0 mm |

Standard cutting angle | 30° |

Materials | D2, HSS-M2, Tungsten Carbide |

Polishing | Standard Ra 1.6 or Mirror-polishing on demand |

Coating of knife edge | On demand |

FAQ

Q: What is shear slitting in industrial converting?

A: Shear slitting is a cutting method where paired top and bottom circular knives create a scissor-like action to slit wide rolls into narrow rolls with clean, precise edges.

Q: Which materials are best suited for shear slitting?

A: Shear slitting is ideal for paper, cardboard, plastic films (PE, PP, PET, PVC), aluminum foil, laminates, nonwovens, textiles, adhesive tapes, and rubber.

Q: What is the difference between shear slitting and razor slitting?

A: Shear slitting delivers higher edge quality, less dust, and better performance on thicker or multilayer materials, while razor slitting is simpler and mainly used for thin films.

Q: What is the difference between tangential and wrap shear slitting?

A: Tangential shear slitting uses a shallow knife intersection on a moving web, while wrap shear slitting wraps the web around the bottom knife for greater stability at high speeds.

Q: What knives are used in shear slitting?

A: Shear slitting uses paired circular knives, typically dished or flat top knives combined with hardened bottom knives or anvils.

Q: Why are dished top knives commonly used in shear slitting?

A: Dished top knives help maintain a stable wrap angle and consistent overlap, improving edge quality when slitting films, paper, and foil.

Q: How important is knife overlap in shear slitting?

A: Correct knife overlap is critical. Too much overlap causes edge damage and wear, while too little overlap leads to incomplete or unstable cuts.

Q: Does shear slitting require lubrication?

A: Yes. When cutting adhesive-coated materials, lubrication prevents glue buildup, reduces friction, and significantly extends knife life.

Q: Where can I order shear slitting knives?

A: Sollex supplies shear slitting knives in D2, HSS-M2, and Tungsten Carbide, including flat and dished circular knives, tailored to slitter rewinder machines.

Shear slitting is the preferred method for converters who need clean, accurate cuts across a wide range of substrates. By choosing the right knife geometry, material, and coating, production lines can achieve consistent slit widths, minimize waste, and reduce downtime. Sollex supplies shear slitting knives in D2, HSS-M2, and Tungsten Carbide, available in flat, dished, and grooved formats. Contact Sollex to order high-performance shear slitting blades designed for your machine and application.

Sollex is a Swedish supplier of industrial knives and machine blades for plastic film, packaging, paper and cardboard industries! We have cutting-edge products that improve manufacturing and converting processes and solve cutting problems. With the right knives and blades, you can get simplified maintenance, time savings, and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Address: Box 5161, 200 71, Malmö, Sweden