Blades for Slitting Thin Stretch Film

High performance blades for slitting and cutting thin stretch film such as: load stability film, waste wrap film, and agricultural film

Content:

- What is stretch film and what is it used for?

- Types of stretch film

- 2 ways to produce stretch film: blown vs cast stretch wrap

- Slitting and winding stretch film inline or in a rewinder

- Sollex developed a blade optimized for thin stretch film

- Improve your stretch film production

In the high-precision world of plastic film manufacturing, the difference between a clean cut and a product mishap can be as thin as the film itself. As a background this article briefly describes what stretch film is used for and how it is produced. In detail this article explains which razor blades that work wonders when slitting thin stretch film inline or in rewinders. This article also shows examples on razor blades that give thin stretch film clean cut edges and work for up to six weeks before blade change is needed.

What is Stretch Film and What is It Used for?

Stretch film, or as it is also called stretch wrap or film for wrapping, is highly stretchable plastic film and used for various purposes, but mainly to protect goods from external agents, avoid damage during shipment and extend the storage life of products. Stretch film is usually made from PE as a raw material. Stickiness is important for stretch film. There are some of main characteristics of stretchable film:

Stretch film, or as it is also called stretch wrap or film for wrapping, is highly stretchable plastic film and used for various purposes, but mainly to protect goods from external agents, avoid damage during shipment and extend the storage life of products. Stretch film is usually made from PE as a raw material. Stickiness is important for stretch film. There are some of main characteristics of stretchable film:

- Ability to stretch and maintain tension

- Usually stretch films are clear, but can also come in different colors

- Stretch films often have one-sided cling properties, meaning they will only stick to themselves

- Many stretch films are recyclable

- Stretch film comes in various thicknesses measured in gauges or microns

- Some stretch films are treated with UV inhibitors to protect the products from sunlight exposure

- Stretchable wrap films provide a barrier against moisture, dust, and debris

The most widely used material for stretch film is Linear Low-Density Polyethylene (LLDPE). LLDPE is valued for its stretchability, durability, and resistance to tearing. In response to environmental concerns, some stretch films are now made from biodegradable plastics. These materials are designed to break down more quickly than traditional plastics.

Types of Stretch Film

Stretch film is used as:

- load stability or pallet stretch film wrap

- packaging stretch wrap

- agricultural film

- waste wrap film

- industrial cling plastic wrapping

- furniture wrapping plastic

- building and converting films

Load Stability Film

Pallet stretch film wrap ensures the safety and security of products in transit. This stretch film for wrapping is a versatile packaging solution, adeptly maintaining the integrity of goods against the jostles and jolts of transportation. Known for its superior elasticity, stretch wrap for packaging is engineered to provide a tight embrace around pallets, effectively shielding them from the common perils of shifting, tipping, and falling.

Pallet stretch film wrap ensures the safety and security of products in transit. This stretch film for wrapping is a versatile packaging solution, adeptly maintaining the integrity of goods against the jostles and jolts of transportation. Known for its superior elasticity, stretch wrap for packaging is engineered to provide a tight embrace around pallets, effectively shielding them from the common perils of shifting, tipping, and falling.

The industrial film wrap made in PE (polyethylene), offers a range of thicknesses to accommodate both light and heavy-duty applications. Wrapping film for packaging not only secures products are also available in recyclable and biodegradable forms. Whether it's enveloping a single pallet with pallet wrapping film or wrapping bulk loads with precision machinery, these films are integral to various industries when it comes to protection. Adopting pallet stretch film wrap is a smart move for businesses looking to merge durability with sustainability in their packaging processes.

Agricultural Film

Agricultural stretch film is transforming the agrarian landscape. Agricultural films shorten the growing season and make it easier for crops to grow. In addition, film provides long-term storage for feed and crops. Leading silage film manufacturers have advanced silage bale wrap film to withstand the rigors of the field while the stretch film baler stands to protect the harvest.

Agricultural stretch film is transforming the agrarian landscape. Agricultural films shorten the growing season and make it easier for crops to grow. In addition, film provides long-term storage for feed and crops. Leading silage film manufacturers have advanced silage bale wrap film to withstand the rigors of the field while the stretch film baler stands to protect the harvest.

Farmers rely on durable silage films and the practical silage roll to protect their precious harvest from the elements. The hay wrap film has become a staple in maintaining the quality of hay bales, while the silage plastic wrap ensures airtight protection that's crucial for fodder quality. Plastic silage wrap for the agricultural sector, and the sturdy bale wrap film are indispensable in the silage wrapping process, safeguarding nutritional value through the seasons. Read more about blades for slitting agricultural film in our other article.

Waste Wrap Film

Waste wrap film plays a crucial role, with plastic film applications like trash bag liners and hazardous waste containment systems ensuring hygienic and efficient waste handling. These films are essential for sanitation, securing waste materials for transport, and supporting sustainable recycling and disposal.

Waste wrap film plays a crucial role, with plastic film applications like trash bag liners and hazardous waste containment systems ensuring hygienic and efficient waste handling. These films are essential for sanitation, securing waste materials for transport, and supporting sustainable recycling and disposal.

The packaging industry relies on plastic wrapping for packaging, where clear plastic wrapping and stretch wrap rolls protect and secure products in transit. Industrial plastic wrapping provides a robust barrier for larger shipments, and stretch wrap film material, known for its elasticity and strength, is vital in both commercial and industrial packaging. Stretch wrapping film, industrial wrapping film, or industrial cling film wrapping safeguards goods with reliability and efficiency.

Building & Converting Film

Multipurpose construction and conversion films serve as a vapor barrier to protect buildings from moisture, or as a carpet pad to strengthen floors and roofs against the elements. With window films, they improve energy efficiency and block harmful UV rays. Conversion films undergo a process of printing, laminating and die-cutting that transforms them into customized packaging and intricate labels that speak to a brand's individuality. These processes transform films into customized solutions that meet the dynamic needs of both businesses and consumers. Conversion films are leading the way, offering a multitude of possibilities that transform spaces and products.

Multipurpose construction and conversion films serve as a vapor barrier to protect buildings from moisture, or as a carpet pad to strengthen floors and roofs against the elements. With window films, they improve energy efficiency and block harmful UV rays. Conversion films undergo a process of printing, laminating and die-cutting that transforms them into customized packaging and intricate labels that speak to a brand's individuality. These processes transform films into customized solutions that meet the dynamic needs of both businesses and consumers. Conversion films are leading the way, offering a multitude of possibilities that transform spaces and products.

2 Ways to Produce Stretch Film: Blown VS Cast Stretch Wrap

Making stretch film is a process that needs technological competence and precision engineering. Stretch film can be made in two different ways: blown and cast stretch wrap. Two distinct methods that impact the film's performance and characteristics. Blown film is known for its superior load-holding force and puncture resistance, whereas cast film offers clarity and quiet unwind.

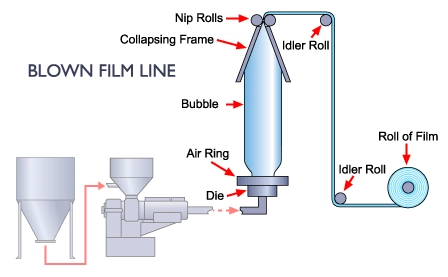

Blown Film Extrusion

Blown film extrusion is a manufacturing process used to produce a wide variety of plastic films, commonly used for packaging materials. The process involves extruding a plastic through a circular die to form a thin-walled tube. Air is then blown into the center of the extruded tube, inflating it like a balloon to several times its initial diameter. As the tube is drawn upwards by rollers, it cools and solidifies into a thin film. The speed of the rollers and the amount of air introduced can be adjusted to control the film's thickness and width. After reaching the desired dimensions, the continuous tube of film can be slit on one or both sides to create flat film layers, or it can be kept as tubing depending on the intended application. This process is versatile and can be used with a variety of thermoplastic materials, including polyethylene and polypropylene, allowing for the production of films with different properties and characteristics.

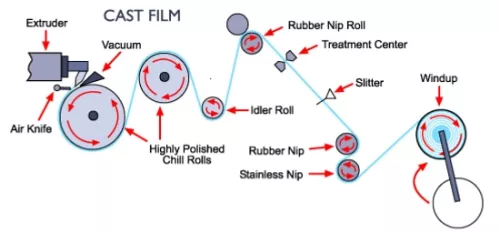

Cast Film Extrusion

Cast Film Extrusion

Cast film is produced using the cast film extrusion process, which involves melting a thermoplastic resin and extruding it through a flat die onto a chilled roll where it is quenched, rapidly cooled, and solidified. As the molten plastic comes into contact with the chilled roll, the cooling process is quick, which results in excellent clarity and gloss properties of the film. Unlike blown film, the cast film process does not involve blowing air into the material; rather, the film is pulled by rolls directly from the die. This method allows for precise control over thickness and width and produces stretchy plastic sheet with outstanding optical qualities and strength.

One of the final steps in the production of polymer stretch film is the cutting of the stretch film into pieces of precise width on film slitter equipment. Cutting of thin stretchable plastic film can be carried out either in the production process, immediately after extrusion inline, or as a separate step on an automatic stretch film rewinding machine. To increase production efficiency, it is advisable to use in-line cutting of the film. Slitting on a plastic film rewinding machine is a separate production operation associated with winding the film onto rolls for distribution. The film rewinding machines then cut the large rolls into narrow sections.

One of the final steps in the production of polymer stretch film is the cutting of the stretch film into pieces of precise width on film slitter equipment. Cutting of thin stretchable plastic film can be carried out either in the production process, immediately after extrusion inline, or as a separate step on an automatic stretch film rewinding machine. To increase production efficiency, it is advisable to use in-line cutting of the film. Slitting on a plastic film rewinding machine is a separate production operation associated with winding the film onto rolls for distribution. The film rewinding machines then cut the large rolls into narrow sections.

You can tell a lot about a film manufacturer's commitment to quality just by looking at the cut edges of the finished product. Are they clean and precise? For cutting thin stretch film at high speeds in-line or on a rewinder, we recommend the 5Z Slotted slitter blades (57 x 19 x 0.40mm) and 4-60-030-Z 3-hole industrial razor blade ( 60 x 22 x 0.30mm) with Zero-friction coating for a clean and even cut.

Slitting blades for IN-LINE stretch film

Slitting film in-line is probably the most complex slitting operation you can have. Blowing or casting film is a technological challenge with myriads of settings to get the wrapping according to specs. Adding the slitting process demands that you cut the film at the same speed as it is blown or casted. This speed and process adds really tough requirements on the blade performance. It needs not just to slit the film perfectly, but it needs to do it at extremely high speeds and often with different thicknesses, additives and characteristics. Adding PIR (Post Industrial Recycling) or PCR ( Post Consumer Recycling) changes the material behavior radically. For slitting thin stretch film inline we have found that 4-60-030-Z slitting razor blade works beautifully.

Slitting film in-line is probably the most complex slitting operation you can have. Blowing or casting film is a technological challenge with myriads of settings to get the wrapping according to specs. Adding the slitting process demands that you cut the film at the same speed as it is blown or casted. This speed and process adds really tough requirements on the blade performance. It needs not just to slit the film perfectly, but it needs to do it at extremely high speeds and often with different thicknesses, additives and characteristics. Adding PIR (Post Industrial Recycling) or PCR ( Post Consumer Recycling) changes the material behavior radically. For slitting thin stretch film inline we have found that 4-60-030-Z slitting razor blade works beautifully.

Slitting blades for stretch film in REWINDERS

Slitting stretch film in a rewinder gives the advantage of being in control of the speed in the cutting or slitting moment. The automatic machines ensure tightly wound rolls and maintain quality, thereby enhancing productivity in packaging operations. Specialized machines, such as PVC or PE slitter rewinder, are used for specific materials. Being in control of the speed you have much lower requirements on blade performance and there are many blades and techniques that are available. For instance you can use shear cutting or razor slitting. And at lower speeds non optimized blades may work. However, our recommendation for 5Z and 4-60-030-Z slitting razor blades still stands when it comes to slit stretch film in a rewinder. But it can’t help to say that slitting film in a rewinder adds a lot of logistical handling that can be avoided if slitting occurs in the inline process.

How Sollex Developed a Blade Optimized for Thin Stretch Film at High Speeds

Not all blades are created equal, especially when it comes to slitting stretched film, a material that demands the utmost precision. Choosing the right industrial blades is an important process. Read what 13 challenges plastic film manufacturers face in our article 13 common problems with cutting plastic film, and what you can do about them.

One of the world's largest stretch film producers asked for help when installing new machines. Specifically the slitting should take place inline (just after it had been blown or casted). Having tons of experience we tested all blades, designs, materials, and coatings possible in many different sessions.

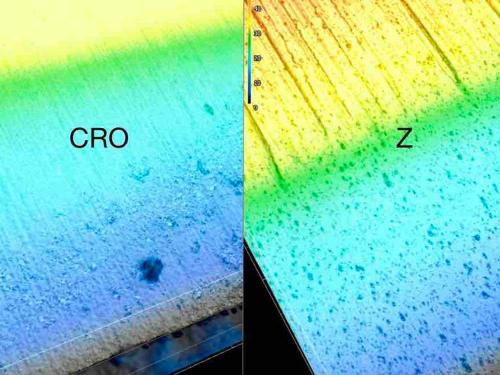

When blades failed, tearing through the film rather than slicing it, Sollex turned to a laser scanning microscope with a display resolution tolerance of 0.5 nanometers. This level of magnification revealed not just the blade's edge, but the very topography that dictates its performance. What Sollex discovered through this lens was a world where microscopic variations could wreak havoc on a macro scale. The typographic scrutiny uncovered why certain blades, identical to the naked eye, performed differently. This knowledge is crucial for manufacturers who rely on consistent, precise cuts to maintain product quality and production efficiency.

Picture 1, above, shows the two blades’ typography zoomed to 50X. You can clearly see the bad blade's thinner coating as the grinding of the steel is visible in the coating. You can also see an area which has disturbances. My guess is that it is these disturbances that ruin the slitting function of the bad blade. In comparison, the coating of the Sollex 5Z blade is thicker but more evenly distributed.

Further analysis, seen in Picture 2, indicates that the bad blade had clusters of topographic tops measuring up to 25 micrometers, which is actually possible to feel if you carefully slide a blade along its edge. The 5Z industrial razor blade had a thicker layer and very few topographic tops. In addition, the edge and coating on the 5Z slitter blade with the zero-friction coating is razor sharp. In contrast, the edge of the bad blade was not straight at all. In 50X enlargement, it looks almost honeycombed. Conclusion: It is hard to use a blade that has a crappy edge due to coating or treatment. Be careful when choosing blades.

Our customer production facility concluded that the 5Z slotted razor blade lasted for seven days. The bad blade had to be replaced after 30 seconds. The 5Z blade works especially good when slitting thin stretched film. Give it a try it may make wonders in your slitting process of thin stretched film.

All old truths about blade hardness and materials had to be put aside as it all came down to keeping the blade straight at high speeds, blade design, and blade edge topography to avoid friction which added dust on the blade and ruined the cut. Sollex's 5Z blade rose to prominence due to its exceptional performance on stretch film, but the quest for innovation didn't stop there. Making the blade thinner and fitting it more tightly took the 4-60-030-Z blade to cutting precision excellence. Our customer and partner, in developing this blade, found that it slits thin stretch film with excellent clean final product output for six weeks before blade change is needed.

Summary

Thin stretch films are used for many everyday applications such as: load stability film, waste wrap film, and agricultural film. Making such film is done by blown or cast film extrusion and slitting. Slitting stretch film correctly is imperative for final product specifications and quality. It can be done in two ways: In-line or in a rewinder machine. For slitting thin stretch film Sollex together with world leading film producers has found that 5Z works really well. For exceptional inline performance and durability when cutting thin stretch film use 4-60-030-Z.

Stretch film is produced using either blown or cast film extrusion. Blown film offers excellent load-holding and puncture resistance, while cast film provides superior clarity and quiet unwinding. After extrusion, the film is slit into precise widths. This can be done inline (during the production process) or separately using a rewinder machine. Inline demands high-performance blades capable of handling varying speeds, thicknesses, and materials. Rewinder slitting is easier but introduces additional logistical handling. Sollex developed the 5Z and 4-60-030-Z blades, optimized for high-speed, thin stretch film slitting. These blades, especially the 4-60-030-Z, have shown exceptional performance and durability, maintaining quality in inline slitting processes for up to six weeks before requiring replacement.

Improve Your Stretch Film Production! Whether you're using blown or cast film our blades ensure cutting edge performance, precision, and durability. Sollex blades minimize downtime and maintain the highest quality standards. Buy our industrial razor blades online and take the first step towards a more efficient, high-quality film production process. You can order Sollex top performance blades for thin stretch film on-line. If you need any support please contact us on info@sollex.com.

FAQ

Q: What is the main characteristic and use of stretch film?

A: Stretch film, or stretch wrap, is a highly stretchable plastic film used primarily to protect goods from damage during shipment and to extend storage life. It is usually made from Linear Low-Density Polyethylene (LLDPE) and has one-sided cling properties.

Q: What are the two primary methods for producing stretch film?

A: Stretch film is produced using either blown film extrusion or cast film extrusion. Blown film offers superior load-holding and puncture resistance, while cast film provides better clarity and a quieter unwind.

Q: What are the two methods for slitting stretch film?

A: Film can be slit in-line (immediately after extrusion), which requires blades capable of extremely high speeds, or as a separate step on a rewinding machine, which has lower blade performance requirements but adds logistical handling.

Q: Which Sollex blades are recommended for cutting thin stretch film at high speeds?

A: Sollex recommends the 5Z Slotted slitter blade and the 4-60-030-Z 3-hole industrial razor blade, both featuring the Zero-friction coating, for a clean and even cut in high-speed, thin stretch film slitting.

Q: How long can the 4-60-030-Z blade last when slitting thin stretch film in-line?

A: In partner production trials, the optimized 4-60-030-Z blade demonstrated exceptional performance and durability, slitting thin stretch film with excellent clean edges for six weeks before a blade change was needed.

Q: Why did Sollex use a laser scanning microscope to develop the 5Z blade?

A: Sollex used a laser scanning microscope with a 0.5 nanometer resolution to examine the blade topography. This proved that microscopic imperfections (topographic tops) or uneven coating were the reasons why identical-looking blades performed poorly, causing friction and ruining the cut.

Q: What factor was found to be the most critical for slitting thin stretch film at high speeds?

A: It was found that all old truths about blade hardness had to be put aside. The critical factors came down to keeping the blade straight at high speeds, the specific blade design, and the blade edge topography to avoid friction.