Blade Recommendations vs. Plastic Polymer Types

In plastic film manufacturing, thermoplastics are the dominant material class. These polymers can be melted, extruded, converted, and reshaped, which makes them well-suited for film extrusion processes like blown film, cast film, and extrusion coating. Several thermoplastic resins are used regularly in the production of flexible films, depending on the performance requirements of the final product.

Polyethylene is the most common thermoplastic used in film manufacturing. Low-density polyethylene, or LDPE, is valued for its flexibility, low sealing temperature, and excellent optical properties. It is widely used in films for packaging, shrink applications, and carrier bags. Linear low-density polyethylene, or LLDPE, offers better tensile strength and puncture resistance than LDPE, which makes it suitable for stretch films, heavy-duty sacks, and multilayer packaging films. High-density polyethylene, HDPE, is used when higher stiffness and moisture barrier are needed. HDPE is commonly used in thinner bags, produce packaging, and films where clarity is not a priority.

Polypropylene is another major thermoplastic used in film applications. Cast polypropylene, or CPP, is soft, transparent, and sealable. It is often used in combination with other materials in laminates. Biaxially oriented polypropylene, BOPP, is stretched in both directions during production, resulting in a film with excellent clarity, dimensional stability, and moisture resistance. BOPP films are widely used in snack food packaging, labels, and decorative applications.

Polyethylene terephthalate, or PET, is a polyester used when high mechanical strength, heat resistance, and gas barrier properties are required. It is common in high-performance packaging films, lidding films, and medical applications. PET is also used as a base layer in laminates where dimensional stability is critical.

Polyamide, typically PA6 or PA66, is used in multilayer films to provide an oxygen barrier and mechanical durability. Vacuum packaging and thermoformed film applications commonly use polyamide when product protection is crucial.

Ethylene-vinyl acetate, EVA, is a polyethylene-based copolymer that adds flexibility, clarity, and improved seal performance to films. It is often used in agricultural films, lamination layers, and specialty packaging where softness or elasticity is needed.

Polystyrene, PS, is used to a limited extent in film. It offers high rigidity and gloss but lacks the toughness of PE or PP. Its use is mostly limited to thermoforming and specialty film applications.

Bioplastics such as polylactic acid, PLA, are also thermoplastics. PLA films are bio-based and industrially compostable, making them suitable for short-life packaging and disposable products. However, their mechanical and thermal performance limits their use in more demanding applications.

Each of these thermoplastic materials plays a role in the film industry depending on the application.

Buy Industrial Blades for Plastic Film Extrusion

Sollex AB is a Swedish company that specializes in the design, manufacture, and distribution of industrial razor blades and cutting tools for the plastic industry. Sollex offers industrial razor blades to cut flexible plastic materials of the following types: PE, LDPE, LLDPE, HDPE, PP, BOPP, PET, PVC, EVA, bio-based and PCR recycled materials.

Sollex AB is a Swedish company that specializes in the design, manufacture, and distribution of industrial razor blades and cutting tools for the plastic industry. Sollex offers industrial razor blades to cut flexible plastic materials of the following types: PE, LDPE, LLDPE, HDPE, PP, BOPP, PET, PVC, EVA, bio-based and PCR recycled materials.

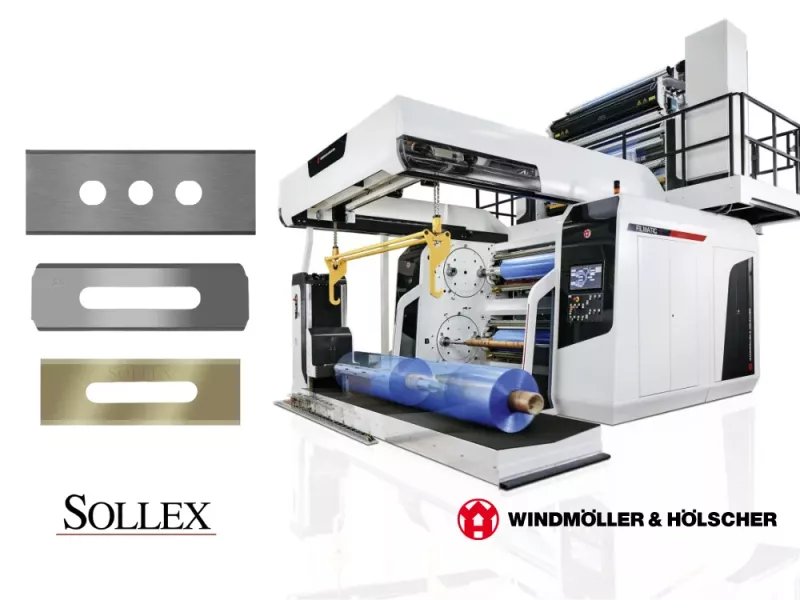

We offer various blade types for plastic film extrusion lines, including slotted slitter blades with rounded and straight corners, straight 3-hole blades, 3-hole slitter rewinder blades with rounded corners, coated film converting blades, and pelletizer blades for plastic recycling.

Firstly, choose a blade design based on which blade holder your machinery has. In general, producers of flexible film should choose the thinnest blade possible to achieve the cleanest cut. Essentially, a blade should be as thin as possible to prevent vibrations and ensure long-term durability. Sollex K blades work wonders for additives in general and specifically chalk. Sollex Z blades are the choice for thin stretch film. For PP, use Sollex V blades. Sollex C blades are optimized for EVA.

Material to cut | Blade recommendation |

|---|---|

PP | |

EVA | |

PE, PET, HDPE, LDPE ( Stretch film ) | |

PE, PET, HDPE, LDPE ( + Calcium carbonate / Caco3 Filler Masterbatch ) | |

PE, PET, HDPE, LDPE ( + Print, Colored ) | |

BOPE, BOPP, CPP | |

Film with paper or paper like materials |

Ordering Sollex industrial blades is an easy process. You can do it online on our website or contact us by mail or phone. Almost all industrial blades are usually in stock. Delivery within Sweden is 1-2 working days; to other countries, about 3-5 working days. If you do not find the slitting blade you are looking for, we can manufacture industrial blades according to your drawing.

You are welcome to contact us at +4635-15 75-00 if you have any questions regarding our industrial machine blades.

![How to Use Scalpels for Precision Cutting and Detailed Work [GUIDE] Skalpeller är perfekta för att skära i olika material som kartong, papper, tapeter, plast, textilier, läder, grafisk design och alla typer av precisionsskärning](https://cdn.starwebserver.se/shops/sollex-se/files/cache/scalpels-for-craft-work-sollex-guide_medium.jpg?_=1644231699)